Sugarcane bagasse packaging offers a promising solution to one of the most pressing environmental issues of our time: the pollution caused by non-biodegradable materials like plastic.

The packaging industry is a significant contributor to global plastic waste, which is heavily relies on plastics that take hundreds of years to break down, leaching harmful chemicals into ecosystems and contributing to massive landfill buildup. This plastic pollution affects wildlife, block waterways, and exacerbates climate change through the release of greenhouse gases.

In contrast, sugarcane bagasse packaging, derived from the fibrous residue of sugarcane after juice extraction, presents an environmentally friendly solution. As a biodegradable and compostable material, sugarcane bagasse decomposes naturally within months, without leaving behind toxic residues.

By using sugarcane bagasse, the packaging industry can make significant strides in reducing its ecological footprint and fostering a healthier planet.

Introduction

In today’s world, where environmental concerns are at the forefront of global discussions, the need for sustainable packaging is important.

With the rise in plastic pollution and the growing burden on our planet’s limited resources, finding eco-friendly alternatives to traditional plastic packaging materials is very important.

Sustainable packaging is not just a trend; it’s a necessity for aligning global movement towards reducing waste, lowering carbon footprints, and protecting our ecosystems for future generations. One such innovative solution making waves in the packaging industry is sugarcane fibers.

Derived from the fibrous residue left after extracting juice from sugarcane, bagasse has traditionally been considered as a waste. However, this so-called waste is now being transformed into a valuable raw material for sustainable packaging, offering an eco-friendly alternative to conventional packaging materials like plastic and soft wood paper.

What is Sugarcane Bagasse?

Sugarcane bagasse is a fibrous material primarily composed of cellulose and is produced in large quantities worldwide. It is a waste byproduct of the sugar industry, generated after the extraction of juice from sugarcane.

Sugarcane (Saccharum officinarum) is extensively cultivated in tropical regions, with a global production of 1.84 billion tons in 2017.

In sugar and alcohol mills, sugarcane is processed, but about 30% of the material remains as a pulpy fibrous residue after processing. This residue is known as bagasse.

Composition of Sugarcane Bagasse

Composition of sugarcane bagasse varies depending on factors such as the sugarcane variety, growing conditions, and processing methods.

However, the general composition of sugarcane bagasse includes:

1. Cellulose

Percentage: Approximately 35-50% of bagasse.

Role: Cellulose is a complex carbohydrate that gives structural support to plant cell walls. It is a primary component of the fibrous structure of bagasse and is used in various applications such as paper and composite materials.

2. Hemicellulose

Percentage: Around 20-30% of bagasse.

Role: Hemicellulose is a group of polysaccharides found in plant cell walls, complementing cellulose. It contributes to the structural integrity of the plant and is partially soluble in alkaline solutions. Hemicellulose is more easily hydrolyzed compared to cellulose and can be used in certain bio-based products.

3. Lignin

Percentage: Approximately 15-25% of bagasse.

Role: Lignin is a complex organic polymer that provides rigidity and resistance to decay in plant cell walls. It is less reactive than cellulose and hemicellulose and is often removed during processes aimed at extracting cellulose. Lignin can be used in certain applications, such as biofuels and composites.

4. Ash

Percentage: Around 3-6% of bagasse.

Role: Ash consists of inorganic mineral components remaining after combustion. It includes minerals such as potassium, calcium, magnesium, and silica. The ash content can affect the quality of bagasse used in certain applications.

5. Extractives

Percentage: Approximately 5-10% of bagasse.

Role: Extractives include various organic substances such as waxes, fats, and resins that can be extracted using solvents. These compounds contribute to the physical and chemical properties of bagasse and can be removed during processing.

6. Moisture Content

Percentage: Typically around 40-50% when freshly collected.

Role: The moisture content affects the handling, processing, and storage of bagasse. Drying is often required to prepare bagasse for further use in manufacturing process.

7. Sugars

Percentage: Minor amounts are present, primarily from residual sugars after juice extraction.

Role: While the primary sugar content is removed during the juice extraction process, some residual sugars may remain in the bagasse. These can sometimes be utilized for further processing or fermentation.

8. Other Components

Percentage: Varies.

Role: Includes various minor components that can influence the overall properties of bagasse, such as proteins and lipids, which are present in smaller quantities.

Understanding the composition of sugarcane bagasse is essential for optimizing its use in various applications, including bio-based products, energy generation, and sustainable packaging materials.

Production of Sugarcane Bagasse Packaging Material

Extracting sugarcane fibers from sugarcane bagasse involves a multi-step process designed to isolate the cellulose fibers from the non-cellulosic components like lignin and hemicellulose.

Here is a procedure commonly used in the industry:

1. Collection and Preparation

Collection: Collect sugarcane bagasse from sugar mills and alcohol mills, where it is generated as a byproduct after juice extraction.

Preparation: Dry the collected bagasse to reduce moisture content, which aids in more efficient processing. The bagasse is usually spread out to dry or subjected to mechanical drying processes.

2. Size Reduction

Shredding: The dried bagasse is fed into a shredder or mechanical mill to break it down into smaller pieces. This increases the surface area for subsequent treatment.

Grinding: Further to reduce the size of shredded bagasse, grinders or pulverizers are used. This step prepares the material for more efficient chemical treatment by creating a finer and more uniform texture.

3. Chemical Treatment

Alkaline Extraction (Kraft Process)

This is a common method for removing lignin and hemicellulose from the mixture, which separates the cellulose fibers.

Preparation of Chemical Solution: Prepare an aqueous solution of sodium hydroxide (NaOH), which can be used in concentrations ranging from 10% to 20%.

Treatment: Mix the ground bagasse with the sodium hydroxide solution in a reactor or digester. The mixture is heated (usually around 160-180°C) under pressure for several hours. This process breaks down lignin and hemicellulose while leaving the cellulose fibers relatively intact.

Washing: After the alkaline treatment, wash the material thoroughly with water to remove residual chemicals and solubilized byproducts.

Bleaching (Optional): To obtain pure cellulose, bleaching can be employed to remove any remaining lignin and other impurities.

Preparation of Bleaching Agents: Use agents such as chlorine dioxide (ClO2), hydrogen peroxide (H2O2), or sodium hypochlorite (NaOCl).

Bleaching Treatment: Treat the washed bagasse fibers with the bleaching agents in a controlled environment. This step is done under specific conditions of temperature, pH, and time to ensure efficient removal of color and remaining lignin.

Final Washing: Wash the bleached fibers thoroughly to remove any residual bleaching agents.

4. Fiber Refining

Mechanical Refining: Use mechanical refiners or beaters to further separate and refine the cellulose fibers from any remaining fine particles and non-fibrous residues. This mechanical processing improves the fiber quality and prepares it for end use.

Screening: Pass the refined cellulose through screens or sieves to sort the fibers by size and remove any remaining impurities.

5. Drying and Final Processing

Drying: Dry the extracted cellulose to reduce its moisture content. This can be done using mechanical dryers, air drying, or specialized drying equipment.

Pulverization (Optional): If needed, the dried cellulose can be further pulverized to achieve a specific particle size or texture suitable for various applications.

6. Quality Control and Testing

Quality Control: Test the extracted cellulose for purity, fiber length, and other quality parameters to ensure it meets industry standards for its intended application.

Adjustments: Based on test results, adjust the extraction process if necessary to improve the quality and performance of the cellulose.

7. Use in Products

Compounding and Blending: The extracted cellulose can be blended with other materials or processed into products such as paper, biodegradable packaging, or composite materials.

Manufacturing: Use the refined cellulose in manufacturing processes to create final products, ensuring it meets the desired specifications and performance criteria.

This comprehensive procedure enables the efficient extraction of cellulose from sugarcane bagasse, transforming a byproduct into a valuable raw material for various industrial applications.

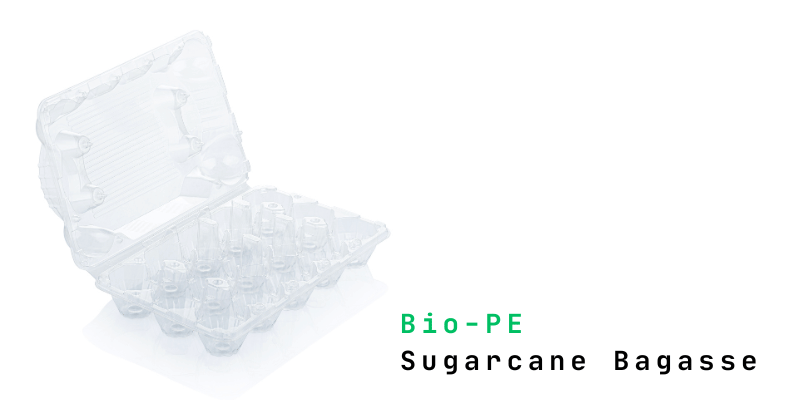

How to Make Bioplastic from Sugarcane or Sugarcane Fibers?

Yes, it is possible to produce bioplastics from sugarcane bagasse, although it often involves using bagasse as a raw material for bio-based plastics or composites rather than directly turning it into plastic.

Here’s how bioplastics can be made from sugarcane bagasse, including the common approaches and processes involved:

Here’s how bioplastics can be made from sugarcane bagasse, including the common approaches and processes involved:

1. Sugarcane Plastic

Bioplastics can be derived from sugarcane by converting the sugars in the cane into plastic materials. This process generally involves the following steps:

A. Sugar Extraction

Juice Extraction: The sugarcane is crushed to extract juice, which is then processed to obtain sugar. The remaining bagasse is a fibrous byproduct.

B. Conversion to Bio-based Plastic

Fermentation: The extracted sugar from sugarcane can be fermented to produce ethanol or other biochemicals. This ethanol can be used to create bio-based plastics such as polyethylenes.

Polymerization: The bioethanol is polymerized to produce bio-based polyethylene (bio-PE) or other types of bio-based polymers. These polymers are chemically similar to conventional plastics but derived from renewable resources.

Braskem: A leading company in bio-based plastics, Braskem produces bio-PE from sugarcane ethanol. While not directly using bagasse, their process involves sugarcane as a key raw material.

2. Composites Plastic from Sugarcane Bagasse

Sugarcane fibers itself can be used in combination with other materials like biopolymer to create biocomposites, which are materials made from a mixture of natural fibers and biodegradable polymers:

A. Preparation of Bagasse

Processing: The bagasse is processed to extract and refine cellulose fibers, which are then used as reinforcement in composite materials.

B. Mixing with Biodegradable Polymers

Blending: The refined cellulose fibers from bagasse are blended with biodegradable polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA). These polymers are sourced from renewable materials and are biodegradable.

Forming: The blend is then molded or extruded into various products, including packaging materials, trays, food containers and other items.

EarthPack: Uses bagasse fibers in combination with biodegradable polymers to create eco-friendly packaging solutions.

Sugarcane Bagasse Products

Sugarcane bagasse is a byproduct of sugarcane juice extraction, which is utilized in various products due to its fibrous nature and sustainability.

Here are some of the most commonly manufactured products from sugarcane bagasse:

Bagasse Food Containers: Includes plates, bowls, trays, and clamshells, often used in takeout and catering services. These bagasse containers are biodegradable and suitable for both hot and cold foods.

Disposable Cutlery: Forks, knives, spoons, and straws made from bagasse are alternatives to plastic utensils.

These biodegradable bagasse containers are safe for hot, cold, and acidic foods, with no risk of harmful chemical leaching. Unlike plastic containers, which may contain BPA, phthalates, and other toxic substances that can leach into food, bagasse containers provide a safer alternative.

2. Sugarcane Paper

Bagasse Paper: Sugarcane fiber is used to produce various types of paper, including writing paper, tissue paper, and industrial paper. This bagasse paper is eco-friendly and often used in both commercial and consumer applications.

Bagasse Cardboard: Sugarcane fiber can be used to manufacture cardboard for packaging and shipping, providing a sustainable alternative to traditional cardboard made from wood pulp.

Unlike traditional paper, which relies on trees that take around 10 years to grow, sugarcane fiber is available annually as a sustainable resource.

3. Sugarcane Plastic Film

Mulch Film: Sugarcane plastic can be used as mulch in gardens and agricultural fields to help retain soil moisture and reduce weed growth.

Benefits of Sugarcane Bagasse Packaging

The shift towards sustainable packaging solutions is driven by the urgent need to protect our environment and reduce our dependency on harmful materials like plastic.

Sugarcane bagasse packaging stands out as a powerful contributor to this mission, offering a range of environmental benefits that make it an ideal choice for eco-conscious consumers and manufacturers.

1. Environmental Impact

Traditional plastic packaging is a major contributor to environmental pollution, with millions of tons ending up in landfills and oceans every year.

In contrast, sugarcane bagasse packaging helps to reduce plastic waste by providing a biodegradable alternative that can naturally decomposes over time.

The reduction of plastic use directly contributes to a lower carbon footprint, as the production of bagasse packaging emits significantly fewer greenhouse gases compared to plastic manufacturing.

Additionally, since bagasse is a byproduct of sugar production, its use in packaging and other products helps to minimize waste and optimize the utilization of available resources.

2. Biodegradability and Compostability

Unlike plastics that can persist in the environment for centuries and degrading environment continuously, bagasse packaging breaks down naturally without leaving behind toxic residues.

Furthermore, sugarcane bagasse is compostable, meaning that it can be processed into nutrient-rich compost rather than ending up in a landfill. When composted, bagasse breaks down into a nutrient-rich fertilizer containing nitrogen, potassium, phosphorus, and calcium, which enriches the soil health.

3. Resource Efficiency

By transforming this agricultural byproduct into valuable packaging material, we maximize the utility of the sugarcane crop, reducing the need for virgin materials and minimizing the environmental impact of packaging production.

4. Versatility and Applications

Sugarcane bagasse can be molded into a wide variety of forms, making it suitable for numerous applications. From food containers and plates to cups and disposable cutlery, bagasse packaging can meet the needs of various industries, particularly in the food service sector.

Its ability to withstand both hot and cold temperatures makes it a practical choice for everything from takeout containers to trays for frozen foods.

This versatility ensures that sugarcane bagasse can replace plastic and styrofoam in many contexts, further reducing the environmental burden of packaging.

Fiber-based Packaging Application

Sugarcane bagasse packaging has found a strong foothold in the food and beverage industry, where the demand for sustainable, disposable packaging is particularly high.

Major companies and fast-food chains have started replacing plastic and styrofoam containers with bagasse-based products. For instance:

1. McDonald’s

McDonald’s has transitioned to using sugarcane bagasse packaging for items like burger boxes and takeaway trays. This highlights the company’s broader sustainability goals, which include reducing plastic waste and lowering carbon emissions across their supply chain.

2. Starbucks

As part of its commitment to environmental responsibility, Starbucks has tested sugarcane bagasse cups and lids in various locations. These bagasse-based products offer an eco-friendly alternative to traditional paper and plastic cups.

3. Whole Foods Market

Known for its focus on natural and organic products, Whole Foods Market has adopted sugarcane bagasse packaging for many of its ready-to-eat food items. This aligns with the retailer’s mission to minimize its environmental footprint and offer customers more sustainable packaging options.

Beyond the food and beverage industry, the cosmetics and personal care sector has also explored sugarcane bagasse packaging. Brands like L’Oréal and Aveda, known for their commitment to sustainability, are using bagasse to package items such as soap dishes, cosmetic trays, and outer packaging for products like shampoos and creams. This shift not only reduces plastic usage but also appeals to eco-conscious consumers who prioritize environmentally friendly packaging.

3. Molded Paper Pulp Tray

While traditionally used for food products, sugarcane bagasse is now being molded into custom-fit packaging for electronics. Companies are using bagasse to create protective packaging for items like smartphones, laptops, and small appliances. This packaging not only provides the necessary protection during shipping but also eliminates the need for Styrofoam that are difficult to recycle.

Find more details on moulded paper pulp packaging here.

4. Seedling Pots for Nursery Garden

In the agricultural industry, sugarcane bagasse is being used to create biodegradable seedling trays and plant pots.

These products can be planted directly into the ground, where they decompose naturally, enriching the soil as they break down.

This innovative use of bagasse supports sustainable farming practices by reducing waste and minimizing the environmental impact of traditional plastic trays.

Case Studies

1. PulpWorks

This U.S.-based company has developed a range of packaging solutions using sugarcane bagasse. One of their notable projects includes creating compostable packaging for personal care products, which has been adopted by several eco-conscious brands.

PulpWorks has won awards for its innovative use of bagasse, demonstrating the material’s potential to revolutionize packaging.

2. Vegware

A leading provider of plant-based packaging, Vegware has integrated sugarcane bagasse into its product line, offering everything from takeaway containers to plates and bowls.

Their use of bagasse has significantly reduced the reliance on plastic and has helped position Vegware as a leader in the sustainable packaging industry.

These examples and case studies highlight how sugarcane bagasse packaging is making a significant impact across various industries. Its adoption not only reflects a growing commitment to sustainability but also highlights the material’s potential to meet diverse packaging needs in innovative and environmentally friendly ways.

What are the Challenges for Sugarcane Bagasse Packaging?

Understanding these challenges is crucial for manufacturers to incorporate sugarcane bagasse into their packaging strategies.

1. Production Costs

Bagasse is a byproduct, so theoretically it is an cheap raw material, but processing it into packaging material or product is more complex and resource-intensive than producing conventional plastic packaging.

The process of pulping, cleaning, and molding of bagasse requires specialized machinery and technology that can be costly.

Additionally, the infrastructure for mass-production for bagasse packaging is not as developed as that for plastic, leading to higher operational costs. These costs can be a barrier for smaller businesses or industries with tight profit margins.

2. Scalability

As the demand for sustainable packaging grows, scaling up the production of sugarcane bagasse packaging to meet global demand poses significant challenges.

The current production capacity may not be sufficient to meet the needs of large multinational companies or widespread adoption across multiple industries.

Scaling up also requires significant investment in manufacturing infrastructure, technology, and skilled labor.

Furthermore, as the production of bagasse packaging increases, there may be a need for more stringent quality control measures to ensure that the material consistently meets industry standards for durability, safety, and performance.

3. Supply Chain

While sugarcane is a widely cultivated crop, particularly in tropical regions, like China, India, Thailand – the availability of bagasse as a raw material can be influenced by several factors.

Sourcing

The production of sugarcane bagasse is directly related to the sugar industry. This means that the availability of bagasse as a raw material for packaging is dependent upon the production of sugar.

Variations in sugarcane harvests due to weather conditions, agricultural practices, or economic factors can impact the availability of bagasse.

In regions where sugarcane is not extensively grown, sourcing bagasse can become a logistical challenge, requiring the transportation of raw materials over long distances, which can increase costs and carbon emissions.

Production

The conversion of bagasse into packaging requires a consistent and reliable supply chain that can manage the various stages of production, from pulping to molding.

Any disruptions in this supply chain, whether due to shortages of raw materials, technical issues in production facilities, or logistical challenges, can lead to delays or increased costs.

Additionally, the seasonal nature of sugarcane harvesting means that the supply of bagasse can fluctuate, potentially leading to periods of scarcity or surplus.

4. Availability

While sugarcane bagasse is abundant in sugar-producing regions, its availability in other parts of the world is more limited. This can pose challenges for global companies looking to standardize their packaging materials across different markets.

In regions where bagasse is not readily available, companies may need to import the material or rely on alternative sustainable materials, which can complicate logistics and increase costs.

Future Trends and Innovations in Sugarcane Bagasse Packaging

The future of sugarcane bagasse packaging is bright, driven by technological advancements and a growing market demand for sustainable packaging solutions.

1. Technological Developments

As the packaging industry evolves, ongoing research and technological innovations are crucial for improving the efficiency and effectiveness of sugarcane bagasse packaging.

Several key areas are emerging as focal points for development:

Enhanced Material Properties

Researchers are working to improve the physical properties of sugarcane bagasse to make it more competitive with traditional packaging materials. This includes enhancing its strength, water resistance, and thermal stability.

For example, advancements in biodegradable coating technologies are enabling bagasse packaging to better withstand moisture and grease, making it more suitable for a wider range of applications, particularly in the food industry.

2. Biocomposites and Hybrid Materials

Biocomposites and hybrid materials are an exciting trend in sustainable packaging. By combining sugarcane bagasse with other natural fibers or biodegradable polymers, these materials achieve improved performance while staying environmentally friendly. For example:

Bagasse and Bamboo Composites: This combination enhances the strength and durability of the packaging, making it suitable for products that require more robust protection while still being biodegradable.

Bagasse with Corn Starch: Mixing bagasse with corn starch results in a material with improved flexibility and strength, ideal for creating versatile packaging solutions that need to withstand various stresses.

Bagasse and Seaweed Extracts: Incorporating seaweed extracts into bagasse can enhance its barrier properties, making it a viable option for packaging items sensitive to moisture or air, such as certain pharmaceuticals and foods.

These hybrid materials offer increased functionality and durability, making them well-suited for packaging applications that need both high performance and environmental benefits.

3. Automation and Manufacturing Efficiency

Technological advancements are making sugarcane bagasse packaging more scalable and cost-effective. Automation and improved production methods are reducing the time and energy required to produce bagasse packaging, which could lower costs and broaden its use across industries. Here are two notable examples:

BioPak: This company has implemented advanced automation in their manufacturing processes, significantly increasing the efficiency of producing sugarcane bagasse packaging. Their use of automated systems helps streamline production, reduce waste, and lower costs, making eco-friendly packaging more accessible to a wide range of businesses.

4. Sustainable Additives

To further enhance the sustainability of bagasse packaging, researchers are investigating natural additives that improve the material’s performance without affecting its biodegradability. Some notable examples include:

Eco-Products: This company integrates plant-based oils and natural waxes into their sugarcane bagasse packaging. Their innovative approach enhances water resistance and durability, making their products suitable for a wider range of applications while maintaining their compostable nature. For instance, their bagasse-based food containers are designed to withstand moisture and grease, making them ideal for hot and cold foods.

Green Label: Green Label uses natural additives such as beeswax in their bagasse packaging solutions. This incorporation improves the material’s barrier properties, providing better resistance to moisture and oils. Their range of biodegradable trays and plates exemplifies how these additives enhance performance while ensuring that the packaging remains environmentally friendly.

These companies are at the forefront of developing sugarcane bagasse packaging with natural additives, making it more functional and sustainable.

Conclusion

Sugarcane bagasse packaging presents a powerful opportunity to make a positive difference. Derived from a renewable resource and fully biodegradable, sugarcane bagasse packaging not only reduces our reliance on plastic but also minimizes waste and carbon emissions.

Incorporating sugarcane bagasse products into our everyday routines, whether in food packaging, disposable tableware, or even in more innovative applications can significantly contribute to reducing our environmental footprint.

This shift not only supports the global mission to combat climate change but also aligns with a broader vision of a circular economy, where materials are reused, recycled, and returned to the earth without causing harm.