In today’s rapidly evolving consumer landscape, the call for eco-friendly solutions is louder than ever. Manufacturers across the globe are stepping up to this challenge by adopting sustainable packaging examples that not only reduce environmental impact but also resonate with the values of environmentally conscious consumers. From biodegradable materials to innovative design strategies, these sustainable packaging examples set a new standard for how products are presented and consumed.

This blog post will explore the top 51 examples, showcasing how forward-thinking companies are leading the charge in creating a greener future. By understanding and implementing these sustainable practices, businesses can significantly contribute to environmental preservation while meeting consumer demand for sustainability.

Introduction to Sustainable Packaging

Sustainable packaging refers to the design and production of packaging solutions that have a reduced environmental impact throughout their entire lifecycle. This approach aims to minimize the use of limited resources, lower carbon emissions, and prevent waste accumulation in landfills or oceans.

Sustainable packaging can be achieved through the use of various sustainable strategies, including:

Recyclable Packaging

Recyclable packaging consists of materials that can be collected, processed, and repurposed into new products. Typical recyclable materials include paper, glass, metals, and specific plastics.

The goal of recyclable packaging is to keep materials in circulation, reducing the need for new raw materials and minimizing waste.

Biodegradable Packaging

Biodegradable packaging is made from materials that are naturally broken down over time through the action of microorganisms.

Unlike petroleum-based plastics, which can take hundreds of years to break down, biodegradable materials like cornstarch, wheat straw plastic, cellulose, and certain bioplastics can decompose within a few months without leaving behind toxic residue.

Compostable Packaging

Compostable packaging goes beyond biodegradability by breaking down into natural elements like water, carbon dioxide, and nutrient-rich compost that can enhance soil health.

These materials include, bamboo packaging, plant-based plastics, paper, and sugarcane bagasse that are designed to decompose under specific composting conditions for turning into nutrient-rich compost that supports soil health and plant growth.

Upcycled Packaging

Upcycled packaging is designed to be repurposed and transformed waste material into something new and valuable, which is extending its life far beyond a single use.

This type of packaging includes items like glass jars, metal cans, and fabric pouches, which can be creatively reused as storage containers, decorative items, or other functional products, reducing waste and giving the packaging a second life.

Why Sustainable Packaging is Needed Today?

Sustainable packaging examples are more important than ever before, as we are facing lots of environmental challenges today.

Traditional packaging, particularly plastics, significantly contributes to pollution, clogs oceans, can take centuries to decompose, and harming ecosystems continuously.

With increasing awareness of climate change, global warming, resource depletion, and plastic waste, the need for sustainable packaging examples that minimize environmental impact is very important to execute.

These sustainable packaging examples use eco-friendly materials, reduce waste, and promote recycling or composting, which are directly addressing these global issues.

By adopting such innovative solutions, companies can reduce their carbon footprints, conserve natural resources, and respond to the consumer demand for eco-products.

Embracing sustainable packaging examples is not just about meeting market demand—it’s about actively contributing to a healthier, more sustainable future for our planet.

List of Sustainable Packaging Examples

By exploring these 51 sustainable packaging examples, you’ll gain insight into how companies around the world are leading the charge toward a more sustainable future.

Whether you’re a manufacturer for inspiration or a consumer interested in supporting eco-friendly products, this information will provide you with a comprehensive look at some of the most exciting developments in sustainable packaging today.

Biodegradable and Compostable Packaging

1. Ooho Edible Water Pods

Ooho Edible Water Pods from Notpla are a groundbreaking example of sustainable packaging, which is designed to address plastic pollution, particularly from single-use plastic bottles.

These pods or water bubbles are made from a biodegradable material derived from seaweed and plants, making them entirely edible and compostable.

Unlike traditional plastic water bottles, which are taking 500-1000 years to breakdown, Ooho pods decompose in just few weeks without leaving toxic residue.

Instead of using petroleum-based plastic bottles, these pods encase water in a thin, jelly-like membrane that can be eaten or composted.

This sustainable packaging example addresses significant environmental issues by reducing the reliance on single-use plastic bottles, which are a major contributor to pollution in our oceans and landfills.

By offering an eco-friendly alternative, Ooho helps to reduce plastic waste, lowers carbon emissions associated with plastic production, and provides the way for more sustainable hydration solutions in everyday life.

Beyond just water, the company is also exploring ways to encase other liquids like fruit juice or edible drinks, providing a versatile and sustainable option for a variety of beverages while cutting down plastic waste significantly.

2. Edible Film Coating for Fruits and Vegetables

Apeel has created an edible film coating for fruits and vegetables that not only extends shelf life but also tackles the global issue of food waste.

Made from plant-based materials, Apeel’s coating acts as an invisible shield that keeps moisture in and oxygen out, dramatically slowing down the spoilage process without using any harmful chemicals.

Unlike traditional plastic packaging, this natural coating helps to keep fruits and vegetables fresh for longer period of time, reducing the need of single-use plastics.

This innovation is crucial in addressing a significant global challenge: nearly 800 million people—about 1 in 10 of the world’s population—go to bed hungry each night, yet one-third of all food is lost or thrown away before it can be eaten.

By keeping fruits and vegetables fresher for longer, Apeel not only helps to reduce food waste but also ensures that more food reach to the consumer.

This sustainable packaging example is reshaping how we think about preserving food, offering a simple, effective, and eco-friendly solution that supports a more sustainable and food-secure world.

3. Milk Protein Packaging

Lactips has developed an innovative sustainable packaging solution using milk protein, creating a biodegradable and water-soluble film that serves as an eco-friendly alternative to traditional plastics.

Made from casein, a protein found in milk, Lactips’ packaging is non-toxic, fully compostable, and safe for the environment.

This film dissolves completely in water, making it ideal for applications like single-dose detergents, food packaging, and more.

Lactips’ milk protein packaging is particularly impactful in reducing plastic pollution and dependence on petroleum-based plastics.

By using natural, renewable resources, this packaging solution helps to cut down waste that typically ends up in landfills and oceans.

The innovative approach not only offers a sustainable packaging example that is gentle on the environment but also highlights the potential of bio-based materials in creating the next generation of packaging solutions.

4. Mushroom Packaging

Ecovative’s Mushroom Packaging, also known as mycelium packaging, is a revolutionary sustainable packaging example that utilizes agricultural waste and mycelium—the root structure of mushrooms—to create a fully compostable material.

Designed to replace harmful materials like Styrofoam, this packaging offers a natural and eco-friendly solution that breaks down completely in just 30 days.

By repurposing agricultural byproducts that would otherwise be burned—contributing to air pollution—Ecovative turns waste into a valuable resource.

The process involves binding these agricultural residues with mycelium to form sturdy, shock-absorbent packaging that can be molded into various shapes for different applications.

This innovative approach not only prevents harmful emissions from burning waste but also reduces reliance on plastic and petroleum-based materials.

Mushroom Packaging is a perfect example of turning waste into the best, showcasing how sustainable materials can help to combat pollution and promote a circular economy.

5. Sugarcane Bagasse Packaging

Huhtamaki India Ltd. has introduced an innovative sustainable packaging solution using sugarcane bagasse, which is the fibrous byproduct left after extracting juice from sugarcane.

This eco-friendly packaging material is biodegradable, compostable, and serves as an excellent alternative to single-use plastics and Styrofoam.

Bagasse packaging not only utilizes waste from sugar and alcohol industries that would otherwise be discarded or burned—reducing air pollution—but also provides a durable, heat-resistant material that is perfect for food containers, plates, and other packaging needs.

Huhtamaki’s sugarcane bagasse packaging highlights a sustainable approach by turning waste into a valuable resource, reducing environmental impact, and supporting the circular economy.

This innovative packaging solution not only cuts down on plastic waste but also helps in creating a cleaner, greener future by transforming agricultural leftovers into practical, earth-friendly packaging.

6. Bio-Capsule Packaging for Coffee

The Coles Group in Australia and New Zealand has introduced Coffee Bio-Capsules, a sustainable packaging example that offers an eco-friendly alternative to traditional coffee pods.

Made from plant-based materials, these capsules are fully compostable, allowing coffee lovers to enjoy their brew without the guilt of contributing to plastic waste.

Unlike conventional coffee capsules, which are often made from plastic or aluminum and can take hundreds of years to break down, Coles’ Coffee Bio-Capsules decompose naturally in compost conditions, turning into nutrient-rich soil that benefits the environment.

This innovative packaging not only reduces plastic pollution but also aligns with growing consumer demand for sustainable and convenient coffee solutions.

By embracing plant-based, biodegradable materials, Coles is setting a new standard for coffee packaging that supports a greener future—one cup at a time.

7. Bio-Blister Packaging

Astellas Pharma Inc., a leading pharmaceutical company in Japan, has developed Bio-Blister Film, a sustainable packaging example aimed at transforming the way medications are packaged.

Traditional blister packs are often made from PVC plastic and aluminum, which are not only difficult to recycle but also contribute significantly to environmental waste, taking hundreds of years to break down.

Bio-Blister Film, on the other hand, is made from biodegradable and renewable materials, offering a greener alternative that decomposes naturally, significantly reducing the environmental footprint of pharmaceutical packaging.

This innovative solution not only minimizes plastic waste but also meets the strict standards require for pharmaceutical products.

Astellas Pharma’s commitment to sustainable packaging highlights how the pharmaceutical industry can shift towards eco-friendly alternatives without compromising on safety and functionality, setting a new standard for environmentally responsible healthcare packaging.

8. Paper Bottle for Pharma

Papacks Germany has developed an innovative solution to pack tablets and capsules.

These paper bottles are designed as a sustainable alternative to traditional plastic packaging (HDPE Bottles), offering a cleaner and greener option for the pharmaceutical industry.

Made from sustainable paperboard, these bottles are fully recyclable and biodegradable.

They can be disposed of easily without contributing to plastic waste, which is a major environmental concern.

The paper bottles are also lightweight, which helps to reduce carbon emissions during transportation.

To protect sensitive pharmaceutical products, like Vitamin D3, Papacks has used a special bio-coating that enhances the barrier properties of the paper bottle, ensuring that the product remains safe, effective, and protected from environmental factors.

Unlike plastic bottles that can take hundreds of years to decompose, the paper bottles from Papacks break down naturally, supporting a circular economy by reducing landfill waste and the pollution of oceans and ecosystems.

By switching to paper bottles for packing tablets and capsules, both manufacturers and consumers can significantly reduce their environmental footprint and help to promote sustainability in the pharmaceutical industry.

Special thanks to Papacks for their groundbreaking innovation, which showcases how industries can rethink packaging solutions to minimize waste and contribute to a cleaner, more sustainable future.

9. Biodegradable BOPP Film

Max Specialty Films Limited has introduced a biodegradable BOPP (Biaxially Oriented Polypropylene) film, a game-changing sustainable packaging example that offers an eco-friendly alternative to traditional plastic films.

BOPP films are widely used in packaging for snacks, confectionery, and other consumer goods due to their excellent barrier properties, clarity, and strength.

However, conventional BOPP films are not biodegradable, contributing to long-term plastic pollution.

Max Specialty Films Limited’s biodegradable BOPP film retains all the beneficial properties of traditional BOPP but is designed to break down naturally in composting environments.

This film decomposes into non-toxic elements, reducing waste and the environmental footprint associated with packaging.

By providing a biodegradable option, Max Specialty Films addresses the growing demand for sustainable packaging solutions that meet industry needs without compromising on performance or contributing to landfill overload.

This innovative packaging example showcases the potential of biodegradable materials to replace conventional plastics, helping to provide the way towards a more sustainable packaging industry.

10. Compostable Cups

Breeze Cups by Duni AB are a remarkable sustainable packaging example designed to replace traditional disposable cups that often end up in landfills.

Made from renewable and biodegradable materials, Breeze Cups are an eco-friendly alternative that offers the same convenience as standard disposable cups without the environmental impact.

These cups are certified compostable, breaking down naturally into non-toxic elements that enrich the soil rather than contributing to waste.

Traditional disposable cups are usually lined with plastic, making them difficult to recycle and harmful to the environment.

Breeze Cups, on the other hand, are crafted with sustainable materials that allow them to decompose quickly under composting conditions, making them ideal for coffee shops, social or corporate events, and any setting where disposable cups are commonly used.

By adopting Breeze Cups, manufacturers and consumers can reduce their carbon footprint, support waste reduction, and contribute to a greener future, showcasing how everyday items can be redesigned to support sustainability without sacrificing convenience.

11. Compostable Food Trays

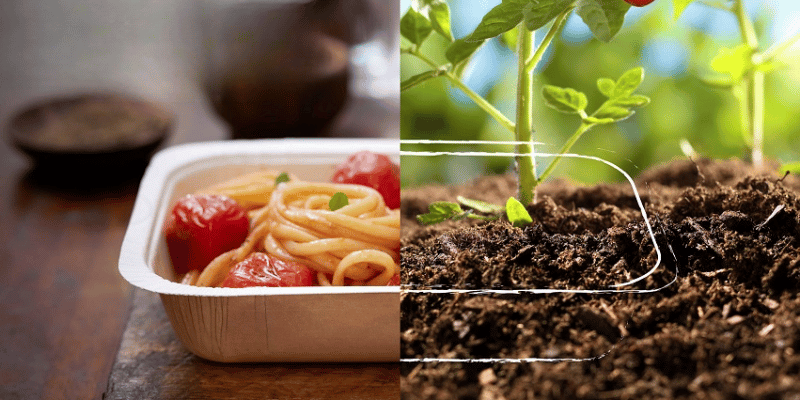

DualPakECO is an innovative sustainable packaging example developed by Confoil in partnership with BASF, designed to revolutionize food packaging with certified compostable trays.

Made from renewable and biodegradable materials, these trays offer an eco-friendly alternative to traditional food packaging that often relies on plastic or polystyrene, which are not biodegradable and contribute significantly to landfill waste.

These compostable trays are perfect for food service, takeaway, and ready-to-eat meals. DualPakECO trays break down completely in composting conditions, turning into nutrient-rich compost that benefits the environment.

They are certified for compostability, ensuring that they meet stringent environmental standards and can be safely composted at home or through industrial composting facilities.

By replacing conventional plastic trays, DualPakECO significantly reduces waste and lowers the carbon footprint of food packaging.

This collaboration between Confoil and BASF showcases how innovative, sustainable materials can provide practical and eco-friendly solutions in everyday food packaging, supporting a circular economy and reducing the impact on our planet.

12. Compostable Garbage Bags

BioBag’s compostable garbage bags are a standout sustainable packaging example, designed to replace conventional plastic trash bags that contribute to long-lasting environmental pollution.

Made from plant-based materials, these bags are fully compostable and decompose naturally in composting conditions, breaking down into organic matter that enriches the soil instead of adding to landfill waste.

Traditional or petroleum-based plastic garbage bags can take hundreds of years to degrade, releasing harmful microplastics into the environment.

In contrast, BioBag’s compostable garbage bags provide an eco-friendly alternative that supports sustainable waste management.

They are perfect for collecting organic waste, such as food scraps, and can be composted along with the waste, creating a closed-loop system that reduces plastic pollution and promotes soil health.

By choosing BioBag, consumers can significantly reduce their environmental impact, demonstrating how small, everyday changes in waste management can lead to a more sustainable future.

Recycled Packaging

13. HDPE Toothpaste Tube

Colgate-Palmolive (India) has introduced an innovative HDPE toothpaste tube, setting a new standard for sustainable packaging in the oral care industry. HDPE is a widely accepted material for recycling, making the HDPE tube easy to process.

Unlike traditional toothpaste tubes, which are often made from a mix of plastic and aluminum or other laminates, making them nearly impossible to recycle, but this HDPE tube is fully recyclable.

Made from High-Density Polyethylene (HDPE), the same material commonly used in milk jugs and other easily recyclable containers, these tubes can be processed in existing recycling systems without any special treatment.

This shift from laminated tubes to HDPE tubes marks a significant step in reducing plastic waste associated with everyday products.

By using a recyclable material, Colgate-Palmolive is addressing the environmental impact of billions of toothpaste tubes that end up in landfills each year.

This sustainable packaging example demonstrates how large brands can adopt innovative materials to promote recycling, reduce waste, and encourage consumers to make more eco-friendly choices in their daily routines.

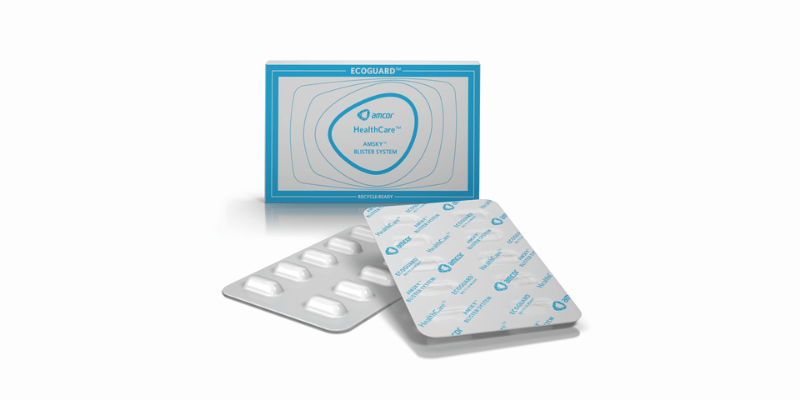

14. HDPE Blister Pack

Amcor USA has developed an HDPE blister pack, a sustainable packaging example that revolutionizes traditional blister packaging commonly used in the pharmaceutical and healthcare industries.

Unlike conventional blister packs made from a mix of PVC and aluminum, which are nearly impossible to recycle, Amcor’s HDPE blister packs are crafted from High-Density Polyethylene (HDPE), which can be fully recycled.

This HDPE blister pack has sufficient barrier properties to protect medications while being very compatible with existing recycling streams.

This innovation not only reduces the environmental impact of pharmaceutical packaging but also addresses the growing consumer demand for more sustainable packaging solutions.

By adopting HDPE blister packs, Amcor is leading the way in reducing waste in the pharma sector, offering a recyclable alternative that aligns with global efforts to enhance sustainability and minimize plastic pollution.

15. Recyclable Blister Pack

Huhtamaki and Klöckner Pentaplast (KP) have collaborated to create a recyclable blister pack, marking a groundbreaking advancement in sustainable packaging for pharmaceuticals and consumer goods.

Traditional blister packs, often made from a combination of PVC and aluminum, which are difficult to recycle and contribute significantly to plastic waste.

The new recyclable blister pack developed by Huhtamaki and KP addresses this issue by using mono-material structures for blister pack that can be fully recycled.

These recyclable blister packs have the essential protective qualities required for pharmaceuticals, such as moisture, gas, and light barriers, while being compatible with existing recycling process.

This innovation not only reduces environmental impact but also aligns with global sustainability goals by offering a practical, eco-friendly alternative to petroleum-based blister packaging.

By transitioning to recyclable blister packs, Huhtamaki and KP are setting a new standard in the industry, helping to reduce waste and promote a circular economy in packaging.

16. PharmaGuard (Blister Pack)

PharmaGuard by SÜDPACK Verpackungen GmbH & Co. KG is an innovative sustainable packaging example designed specifically for the pharmaceutical industry.

This advanced packaging solution offers high-barrier protection for sensitive medications while being more environmentally friendly compared to traditional plastic-based materials.

PharmaGuard is developed using recyclable mono-materials that provide the necessary barrier properties to protect drugs from moisture, oxygen, and other external factors without compromising recyclability.

Traditional pharmaceutical packaging often involves complex multi-material structures that are difficult to recycle, contributing to waste.

PharmaGuard addresses this issue by utilizing recyclable materials that are compatible with existing recycling process, significantly reducing environmental impact.

This sustainable packaging solution not only meets the stringent requirements of pharmaceutical packaging but also aligns with the growing demand for eco-friendly alternatives in healthcare.

SÜDPACK’s commitment to innovation with PharmaGuard showcases how the industry can shift towards greener solutions without sacrificing quality or safety.

17. Aircushion from Paper

PaperWave Bio, developed by Flöter Verpackungs-Service GmbH in Germany, is an innovative sustainable packaging example designed to replace traditional plastic bubble wrap and other non-biodegradable cushioning materials.

Made from renewable paper and coated with a bio-based film, PaperWave Bio provides excellent protective cushioning for shipping fragile items while being fully compostable and biodegradable.

Unlike conventional plastic cushioning, which contributes to long-term waste and environmental pollution, PaperWave Bio decomposes naturally without leaving harmful residues.

It offers the same level of protection as petroleum-based plastic but with a significantly lower environmental footprint.

This eco-friendly cushioning solution is ideal for e-commerce, retail, and other industries looking to reduce their reliance on petroleum-based plastic packaging.

By choosing PaperWave Bio, companies can protect their products during transit while supporting sustainability efforts, demonstrating a commitment to eco-friendly packaging that helps to preserve future generation and planet.

18. Aircushion from Compostable Plastic

ClimaFilm-100 Blue Angel by Flöter Verpackungs-Service GmbH is a sustainable packaging example that redefines eco-friendly stretch films used for securing and protecting goods during transportation.

Certified with the prestigious Blue Angel eco-label, this film is recognized for its low environmental impact, resource efficiency, and reduced carbon footprint.

Unlike conventional stretch films, which are often made from virgin plastics and contribute to plastic waste, ClimaFilm-100 is made from recycled materials and is fully recyclable.

It provides excellent stretchability and strength, ensuring goods are securely wrapped while minimizing material usage.

This innovative film helps companies to reduce plastic consumption and supports a circular economy by integrating sustainable practices into everyday logistics and packaging operations.

By using ClimaFilm-100 Blue Angel, manufacturer can significantly lower their environmental impact, demonstrating a commitment to sustainability while maintaining the quality and reliability needed for product protection.

19. Recycled PET Bottles

Goodman Fielder, a leading food company in Australia and New Zealand, has introduced recycled PET (rPET) bottles as a sustainable packaging example that supports a circular economy.

These bottles are made from recycled polyethylene terephthalate (PET), reducing the need for virgin plastic and minimizing the environmental impact associated with plastic production.

Unlike traditional PET bottles that depends on new petroleum-based polymer, rPET bottles are made from post-consumer plastic waste, which is cleaned, processed, and repurposed into new bottles.

This approach not only diverts plastic waste from landfills and oceans but also conserves natural resources and reduces greenhouse gas emissions associated with plastic manufacturing.

Goodman Fielder’s commitment to using recycled PET packaging demonstrates how manufacturer can take an active role in reducing plastic waste, promoting recycling, and supporting a more sustainable future by closing the loop on plastic use.

20. Recyclable Mono-Material Pump

Aptar, in collaboration with Dermalogica, has developed a recyclable mono-material pump, which set a new benchmark in sustainable packaging for the personal care industry.

Unlike conventional pumps that are often composed of multiple materials, making them difficult to recycle, Aptar’s innovative design uses a single recyclable material throughout the entire pump.

This ensures that the pump can be recycled easily, along with its compatible bottle, reducing waste and simplifying the recycling process.

This sustainable packaging example addresses a significant challenge in the beauty and skincare market, where pumps are commonly used but rarely recycled due to their complex construction.

Aptar’s mono-material pump maintains the high performance and user experience that consumers expect while contributing to a circular economy.

By adopting this eco-friendly packaging, Dermalogica and Aptar are leading the way in reducing plastic waste and promoting responsible, recyclable packaging solutions in the personal care industry, aligning with growing consumer demand for sustainable products.

21. Waste into Valuable (Ecoallene®)

Ecoallene® by Unifarco Spa is an innovative sustainable packaging example that transforms waste into valuable materials.

Developed in Italy, Ecoallene® is made from recycled multilayer packaging waste, such as Tetra Pak cartons, which traditionally pose recycling challenges due to their complex mix of paper, plastic, and aluminum layers.

Ecoallene® addresses this issue by converting these difficult-to-recycle materials into a fully recyclable plastic alternative.

The resulting material is durable, lightweight, and suitable for various applications, including packaging, consumer goods, and everyday items.

Ecoallene® not only helps to divert waste from landfills but also supports a circular economy by giving new life to materials that would otherwise be discarded.

By using Ecoallene®, companies can reduce their environmental footprint, support waste reduction efforts, and contribute to a more sustainable future, showcasing how innovative recycling technologies can turn complex waste streams into practical, eco-friendly solutions.

Upcycled Packaging

22. Recycled Ocean Plastic Packaging

Ocean Shoes by Adidas represent a groundbreaking sustainable packaging and product innovation, turning marine plastic pollution into stylish, high-performance footwear.

Partnering with Parley for the Oceans, Adidas collects plastic waste from beaches, coastal communities, and oceans, transforming these waste plastic bottles into yarn for making shoes.

Each pair of shoes is made using upcycled plastic waste, including plastic bottles, fishing nets, and other discarded debris that would otherwise contribute to ocean pollution.

This eco-friendly method not only cut down plastic pollution in our oceans but also showcases the potential to transform discarded materials into valuable products.

Ocean Shoes serve as a powerful example of how companies can address environmental issues while meeting consumer demand for sustainable and innovative products.

Adidas’ commitment to turning ocean plastic into wearable, durable footwear not only raises awareness about marine pollution but also supports a circular economy by integrating recycled materials into mainstream fashion and sportswear.

23. Upcycled Clothing Fabrics

Patagonia, a leader in sustainable fashion, has pioneered the use of upcycled clothing materials by repurposing old clothes into new, high-quality garments.

This innovative approach involves collecting used clothing, which would otherwise end up in landfills, and transforming these fabrics into new stylish garments.

Patagonia’s upcycling process not only reduces textile waste but also conserves natural resources by minimizing the need for new raw materials.

By upcycling old clothes, Patagonia turns waste into wearable, stylish, and durable apparel that aligns with the brand’s commitment to environmental responsibility.

This sustainable packaging and production method not only addresses the issue of fast fashion waste but also encourages consumers to rethink their clothing choices.

Patagonia’s efforts demonstrate how upcycling can create a circular economy in the fashion industry, where old garments are given new life, reducing environmental impact and promoting more responsible consumption habits.

24. Wheat Straw Plastic Products

With global wheat production exceeding 780 million metric tons annually, vast quantities of wheat straw are generated as a by-product.

Wheat straw, typically left as waste in fields, often undergoes burning, contributing to severe air pollution and environmental harm.

However, this abundant, underutilized resource holds immense potential when repurposed into sustainable packaging solutions.

Instead of burning, wheat straw can be processed into cellulose bioplastic or combined with biopolymers to create composite packaging materials.

These materials are not only eco-friendly but are also free from harmful chemicals such as phthalates and BPA, making them safe for food packaging, including plates, containers, and cutlery.

By transforming wheat straw waste into valuable, sustainable packaging, this innovative approach addresses agricultural waste management issues and promotes a circular economy.

Wheat straw plastic products exemplify how agricultural by-products can be redirected from landfills and pollution-causing practices into high-value, eco-friendly packaging solutions.

Reduce use of Plastic

25. Recycled Paper Bottles

Ecologic Brands has introduced an innovative packaging solution with their recycled paper bottles, offering a sustainable alternative to traditional plastic packaging.

These eco-friendly bottles are made primarily from recycled cardboard and newspaper, with an inner liner that uses minimal plastic.

This unique combination significantly reduces the amount of plastic needed compared to conventional bottles, making the packaging both lightweight and environmentally friendly.

Recycled paper bottles are designed to be easily separated into paper and plastic components, allowing consumers to recycle both parts effectively.

This approach not only reduces the carbon footprint associated with plastic production but also helps to divert waste from landfills.

Ecologic Brands’ sustainable packaging example showcases how innovative design can transform everyday products that meets consumer demand for greener packaging while helping to combat plastic pollution.

26. Paper Packaging for Soap

Huhtamaki India Ltd. has developed sustainable paper soap wrappers, providing an eco-friendly alternative to traditional plastic and aluminum-coated packaging.

These wrappers are crafted from biodegradable and recyclable paper materials, designed to protect the soap while significantly reducing environmental impact.

By using paper-based and compostable solutions, Huhtamaki addresses the growing need for greener packaging in the personal care industry.

Traditional soap wrappers often use non-recyclable materials that end up in landfills, contributing to environmental pollution.

In contrast, Huhtamaki’s paper soap wrappers decompose naturally, supporting a circular economy and minimizing waste.

This innovative packaging not only fulfills the practical needs of protecting and preserving soap but also aligns with consumer demand for sustainable products.

Huhtamaki’s commitment to use paper for soap packaging demonstrates how everyday items can be redesigned to reduce their environmental footprint.

27. Paper Packaging for Chocolate

KANAOKA Holdings Co. Ltd. and Mitsubishi Paper Mills Limited have developed an innovative chocolate paper wrapper, offering a sustainable packaging solution for the confectionery industry.

Traditionally, chocolate is wrapped in plastic or laminated foil, which are not easily recyclable and contribute to significant environmental waste.

This new wrapper is made from specially designed paper, which is both biodegradable and recyclable, providing an eco-friendly alternative without compromising on product protection.

The chocolate paper wrapper maintains excellent barrier properties to protect chocolate from moisture and external contaminants, ensuring the quality and freshness of the product.

By using renewable paper materials, this packaging solution supports a reduction in plastic waste and aligns with consumer demand for sustainable packaging.

KANAOKA and Mitsubishi Paper Mills show how we can rethink traditional packaging to be more eco-friendly. Their work provides a greener choice that makes everyday items like chocolate more sustainable.

28. Paper-based Packaging

UPM Specialty Papers and Fazer have developed a fully fibre-based chilled food packaging solution that revolutionizes the way fresh foods are packaged.

Designed as a sustainable alternative to plastic and mixed-material packaging commonly used for chilled and refrigerated products, this innovative packaging is made entirely from renewable, recyclable fiber materials.

This packaging solution provides excellent barrier properties, protecting chilled foods from moisture and external contaminants while maintaining product freshness.

Unlike conventional plastic packaging that is difficult to recycle, UPM and Fazer’s fibre-based packaging can be easily recycled within standard paper recycling streams, significantly reducing environmental impact and supporting a circular economy.

This example highlights the potential of natural materials in reducing plastic waste in the food industry.

By replacing traditional packaging with a fully fibre-based option, UPM and Fazer are setting a new standard for eco-friendly food packaging, offering a practical and planet-friendly alternative that meets the growing demand for sustainable packaging in the food sector.

29. Eco Scoop for Laundry Powder

Eco Scoop by Earthwise Group Limited, based in Australia and New Zealand, is a sustainable packaging example that replaces traditional single-use plastic scoops commonly found in household products.

Made from paper-based material, the Eco Scoop is designed to reduce plastic waste associated with conventional scoops that are often discarded after minimal use. Additionally, this eco-scoop is part of box packaging without using extra material.

This innovative scoop not only provides the same functionality for measuring and dispensing powder but also decomposes naturally when disposed of without leaving harmful residues.

By using plant-based and eco-friendly materials, Earthwise Group Limited supports the reduction of single-use plastics and promotes a more sustainable approach to everyday items.

The Eco Scoop demonstrates how thoughtful design can lead to environmentally responsible packaging solutions, encouraging consumers to make greener choices while maintaining convenience and practicality in their daily routines.

30. Toothbrush with Replaceable Head

Colgate-Palmolive’s new replaceable head toothbrush is a pioneering sustainable packaging example in the oral care industry.

This innovative toothbrush features a durable handle designed to last, paired with a replaceable brush head that can be swapped out when needed.

By focusing on replaceable heads, this product significantly reduces plastic waste compared to traditional disposable toothbrushes, where the entire brush is discarded after use.

The replaceable head system uses up to 80% less plastic than conventional toothbrushes, aligning with Colgate-Palmolive’s commitment to reduce plastic waste and promoting a circular economy.

The durable handle can be reused multiple times, and the easily replaceable heads provide the same level of dental hygiene without the environmental impact.

This approach not only cuts down on plastic waste but also offers consumers a practical and cost-effective solution that supports sustainable living.

Colgate’s replaceable head toothbrush highlights how simple design changes can have a big impact on reducing waste and promoting a more eco-friendly lifestyle.

31. Plastic-free Packaging for Toothbrush

Karl Knauer KG, in collaboration with GSK Consumer Healthcare and M+C Schiffer, has introduced plastic-free toothbrush packaging for Aquafresh and Dr.BEST brands, setting a new benchmark in sustainable oral care packaging.

This innovative packaging solution eliminates traditional plastic blister packs, replacing them with recyclable and compostable cardboard made from renewable sources.

The plastic-free packaging not only reduces environmental impact but also aligns with growing consumer demand for eco-friendly products.

It effectively protects the toothbrush during transportation and displays the product attractively on store shelves without the use of non-recyclable materials.

This move away from plastic packaging reflects a commitment to sustainability and supports the broader push toward reducing single-use plastics in everyday consumer goods.

By adopting fully recyclable paper-based packaging, Karl Knauer, GSK, and M+C Schiffer are leading the way in making oral care products more sustainable, demonstrating that even small changes in packaging design can significantly contribute to reducing plastic waste and promoting a greener future.

32. Tapeless Delivery System for Logistics

CJ Logistics has introduced a groundbreaking sustainable packaging example with their Tapeless Delivery Packaging Solution, which includes the Invoice Type Tape and One Touch Box.

This innovative approach eliminates the need for traditional BOPP plastic tapes and adhesive seals, significantly reducing packaging waste in the logistics and e-commerce sectors.

The Invoice Type Tape is an integrated label system that secures the package while displaying shipping information or invoice, eliminating the need for separate plastic tapes.

The One Touch Box is designed with a smart locking mechanism that securely closes without the need for additional tape, making packaging and unpacking faster and more convenient.

These tapeless packaging solutions not only streamline the delivery process but also minimize plastic waste and improve recyclability.

By removing conventional BOPP tapes and adhesives, CJ Logistics is promoting sustainable shipping practices that reduce environmental impact, enhance packaging efficiency, and support a greener, more sustainable approach to delivery services.

33. Mono-material Retort Pouch

The Mono-Material Retort Pouch developed by Flavour Makers and Toppan Inc. is an innovative sustainable packaging example that transforms how we package ready-to-eat meals and other food products.

Unlike traditional multi-layered pouches, which combine different materials that are difficult to recycle, this retort pouch is made from a single recyclable material, making it easier to process in existing recycling streams.

Designed to withstand high temperatures used in sterilization, the Mono-Material Retort Pouch offers excellent barrier properties to preserve food quality and extend shelf life while being fully recyclable.

This packaging solution addresses the growing need for sustainability in the food industry, where convenience often comes at the cost of environmental impact.

By adopting mono-material technology, Flavour Makers and Toppan Inc. are reducing plastic waste and promoting a circular economy, demonstrating that food packaging can be both practical and planet-friendly.

34. PCR Laminated Tube

EPL Limited Europe presents a Sustainable Packaging Example with its 100% recyclable PCR (Post-Consumer Recycled) laminated tubes.

These tubes are crafted from recycled plastic materials, helping to reduce plastic waste by utilizing materials that would otherwise end up in landfills.

By decreasing the need for virgin plastic, these tubes contribute to lowering greenhouse gas emissions and conserving natural resources.

This sustainable packaging example supports a circular economy, where waste is minimized, and materials are continually reused, aligning with the growing demand for eco-friendly packaging solutions in the personal care, cosmetic, and pharmaceutical industries.

Innovative Packaging

35. Label Free Bottle Packaging

The Label-Free Coca-Cola Bottle from Japan is an innovative Sustainable Packaging Example that eliminates the need for plastic labels on PET bottles by directly printing matter onto the bottle or integrated into its design.

By removing BOPP labels from PET bottles, Coca-Cola reduces the complexity of the recycling process, making it easier for the bottles to be efficiently sorted, cleaned, and recycled.

This approach helps to lower plastic waste and conserves resources by simplifying the recycling stream.

Additionally, it reduces the amount of ink and adhesives used, further minimizing the environmental impact.

This sustainable packaging example demonstrates how rethinking traditional designs can lead to significant environmental benefits, aligning with global efforts to reduce plastic pollution and enhance recycling efficiency.

36. Liner-less Label Packaging

The Linerless Label from HERMA InNo Liner, developed by Result Group, is an advanced Sustainable Packaging Example that eliminates the need for traditional release liners in self-adhesive labels.

By removing the backing liner, this solution not only reduces waste and material consumption but also allows the label rolls to be wound more compactly.

This compact design increases the length of label rolls, reducing the frequency of roll changes during production and minimizing machine stoppages.

Consequently, it enhances production efficiency by maintaining continuous operations and reducing downtime.

The special adhesive used in HERMA InNo Liner activates only during application, ensuring a secure bond without extra materials.

This innovative design cuts down on CO2 emissions linked to the production and disposal of liners and supports a circular economy by making the entire label recyclable.

It offers a practical and eco-friendly alternative to conventional labels, addressing industry needs for higher productivity while aligning with global sustainability objectives.

37. Copper-based Film Packaging

LifeSpan™ Copper-based Film, developed by Amcor Flexibles Chile and CopperProtek, is a pioneering Sustainable Packaging Example that integrates copper nanoparticles directly into the film to utilize copper’s natural antimicrobial properties.

This advanced packaging solution addresses the critical need for effective antimicrobial barriers without relying on traditional chemical preservatives or coatings, which can have environmental and health concerns.

By embedding copper nanoparticles, the film actively reduces bacterial growth, extending the shelf life of perishable goods and significantly reducing food waste—a major global issue.

LifeSpan™ is designed to maintain the freshness of products, supporting a more sustainable food supply chain by lowering spoilage rates.

In addition to its antimicrobial benefits, the film is fully recyclable, making it an environmentally friendly alternative to conventional plastic films.

This innovation aligns with circular economy principles, emphasizing resource efficiency, waste reduction, and improved recyclability.

LifeSpan™ Copper-based Film demonstrates how nanotechnology can be leveraged to create safer, more sustainable packaging solutions that meet the growing demand for eco-friendly products.

38. AgroLife®

AgroLife® by Smurfit Kappa is a revolutionary Sustainable Packaging Example crafted to redefine the agricultural packaging landscape.

This innovative solution features specially designed corrugated cardboard trays coated with a unique formula that actively absorbs ethylene gas—a natural compound emitted by fruits and vegetables that accelerates ripening and shortens shelf life.

By targeting ethylene gas, AgroLife® significantly slows down the ripening process, keeping fruits fresh for longer periods.

The unique design on the trays optimizes ventilation and moisture control, enhancing product preservation from farm to consumer.

This breakthrough technology not only reduces food waste but also minimizes carbon footprints by extending the shelf life of fruits.

AgroLife® is fully recyclable, renewable, and biodegradable, providing an eco-friendly alternative to plastic crates or packaging.

This innovative packaging supports a circular economy and meets the growing demand for sustainable solutions, making AgroLife® an essential choice for growers and retailers committed to reduce waste and delivering high-quality, fresh products to the market.

39. Stretch Wrap Paper Packaging

SeaStretch by RAJA Norway is an innovative Sustainable Packaging Example that introduces the world’s first manual stretch wrap made entirely of paper.

This ground-breaking product is designed to replace traditional plastic stretch films used for securing pallets and packages during transportation.

Made from sustainably sourced paper, SeaStretch is strong, flexible, and easy to use, offering a reliable alternative to plastic wraps without compromising on performance.

SeaStretch significantly reduces plastic waste and the environmental footprint associated with packaging by utilizing renewable and biodegradable materials.

During use, the paper wrap can stretch and cling around goods, providing the same protective qualities as plastic, but with the added benefit of being recyclable in standard paper waste streams.

SeaStretch aligns with RAJA’s commitment to sustainable solutions, offering companies a greener way to secure their shipments, reduce plastic consumption, and contribute to a circular economy.

It exemplifies how simple changes in packaging materials can have a profound impact on sustainability efforts across industries.

40. Paperboard Bottle for Wine

Frugalpac’s Paperboard Bottle for Wine is a new, eco-friendly packaging that replaces traditional glass wine bottles with a more sustainable option.

This innovative bottle is made primarily from recycled paperboard, with an internal food-grade liner to ensure the wine’s integrity and flavor.

Weighing significantly less than a conventional glass bottle, this packaging not only reduces carbon emissions during production and transport but also uses up to six times less carbon and water compared to traditional glass bottles.

The lightweight design makes it easy to carry, and the bottle’s paperboard construction is fully recyclable, aligning with circular economy principles.

The Frugalpac bottle provides a lower environmental impact option for wine producers and consumers, allowing them to enjoy their favorite beverages with a significantly reduced carbon footprint.

By replacing glass with paperboard, this packaging innovation addresses the global demand for more eco-friendly alternatives, demonstrating how material innovation can drive sustainability in the beverage industry while maintaining product quality and aesthetics.

41. Sustainable Bio-capsules

The Sustainable Bio Capsule from Ambipar is an innovative Sustainable Packaging Example that transforms waste into seed capsules for reforestation.

Developed using biodegradable collagen derived from pharmaceutical industry waste, these capsules contain seeds of native plants combined with composted biomass from the cellulose industry.

The capsules are designed to be launched remotely using drones, targeting remote or degraded areas that are difficult to access through traditional reforestation methods.

Upon contact with water, the capsules dissolve, releasing nutrients and activating the seeds, which enhances the probability of germination, especially in soils affected by deforestation, erosion, or wildfires.

This technology not only supports environmental restoration but also promotes the circular economy by repurposing industrial waste and boosting the economic development of traditional communities by sourcing seeds from local cooperatives.

Ambipar’s innovation has received multiple awards for its impact on reforestation and sustainable land management.

42. Cardbox Packaging or Design Packaging

Cardboard Packaging from the Czech Republic, recognized at the WorldStar Packaging Awards 2023, is a Sustainable Packaging Example that utilizes recyclable and biodegradable materials.

This packaging solution, designed by Cardbox Packaging, stood out for its eco-friendly approach, focusing on reducing plastic usage and promoting sustainability in packaging.

The cardboard material is sourced from sustainably managed forests and is fully recyclable, helping to decrease environmental impact by lowering carbon emissions and minimizing waste.

This innovation supports the transition to a circular economy, where materials are reused and waste is significantly reduced, making it an excellent sustainable choice for the food industry and beyond.

43. Hug&Hold Packaging

Hug&Hold by Mondi is an innovative Sustainable Packaging Example that replaces traditional plastic shrink wrap with a fully recyclable, paper-based solution for bundling multipacks of beverages.

Made from responsibly sourced paper, Hug&Hold combines a corrugated cardboard sleeve and a uniquely designed handle that securely holds bottles in place without the need for plastic.

This packaging not only reduces plastic waste but also lowers the carbon footprint associated with production and disposal.

Hug&Hold supports the circular economy by being 100% recyclable in existing paper waste streams, providing brands with an eco-friendly alternative that meets sustainability goals and appeals to environmentally conscious consumers.

44. Cardboard Toy from Packaging

Stora Enso Packaging introduces a creative and Sustainable Packaging Example with its Book Packaging that includes a Cardboard Toy.

This innovative packaging solution is designed to not only protect books during shipping but also provide an added element of fun and functionality.

The cardboard toy, which can be easily assembled from the packaging itself, engages children and adds value beyond the typical unboxing experience.

This multi-purpose design reduces waste by repurposing the packaging into a toy, encouraging recycling and reuse.

The packaging is made from sustainably sourced cardboard, fully recyclable, and aligned with Stora Enso’s commitment to promote a circular economy.

By transforming packaging waste into a playful item, this solution enhances the user experience while significantly lowering environmental impact.

It provides a unique way to make packaging more interactive and eco-friendly, appealing to environmentally conscious consumers who value sustainability and creativity in everyday products.

45. SPOPS Paper Container

SPOPS Paper Container by Nippon Paper Industries Co., Ltd. is an innovative Sustainable Packaging Example from Japan that focuses on reducing plastic usage through its paper-based design.

SPOPS stands out as a versatile and eco-friendly alternative to conventional plastic containers, offering high durability and moisture resistance thanks to its unique design and technology.

The container is designed to handle various products, including food and personal care items, providing a sustainable option without compromising on functionality.

This packaging solution reduces the environmental impact by utilizing renewable materials sourced from responsibly managed forests and is fully recyclable, aligning with the principles of a circular economy.

The SPOPS container not only minimizes plastic waste but also supports carbon footprint reduction through lower raw material usage and energy consumption in production.

By integrating innovative paper technologies, Nippon Paper Industries demonstrates a commitment to sustainable development, offering an effective alternative to traditional plastic packaging that meets both environmental and consumer needs.

46. Self-separating Cup Packaging

K3® r100 by Greiner Packaging International GmbH is a cutting-edge Sustainable Packaging Example that redefines convenience and recyclability in the packaging industry.

This innovative self-separating cup features a unique design where the cardboard outer sleeve automatically detaches from the plastic cup during the recycling process, allowing each material to be efficiently recycled in its appropriate waste stream.

This self-separating mechanism simplifies the recycling process for consumers and significantly improves recycling rates.

The K3® r100 cup is made from 100% recyclable materials, promoting a circular economy by reducing waste and enhancing the recyclability of single-use packaging.

The cardboard sleeve not only provides insulation but also reduces the plastic content by up to 50%, making the cup lightweight and eco-friendly.

By focusing on ease of separation and material reduction, K3® r100 supports sustainability goals without compromising on functionality or aesthetics, setting a new standard in environmentally responsible packaging for food and beverage industries.

47. Vaccine Protector from Planet Protector Packaging Pty Ltd

Vaccine Protector by Planet Protector Packaging Pty Ltd is an innovative Sustainable Packaging Example specifically designed to ensure the safe and eco-friendly transport of vaccines.

Unlike traditional polystyrene-based packaging, the Vaccine Protector uses Woolpack technology, which leverages the natural insulating properties of sheep wool to maintain temperature control.

This biodegradable and compostable solution is an excellent alternative to plastic-based cold chain packaging, offering superior insulation performance without harming the environment.

The wool fibers act as a natural thermal barrier, maintaining the required temperature for sensitive pharmaceuticals, including vaccines, throughout the supply chain.

This packaging solution reduces the reliance on fossil-fuel-based materials and minimizes waste by providing a fully compostable option at the end of its life cycle.

By combining high-performance thermal protection with sustainability, the Vaccine Protector supports global efforts to reduce plastic pollution while ensuring the safety and efficacy of critical medical supplies.

It exemplifies how innovative, natural materials can revolutionize protective packaging in the healthcare industry.

48. Water-based Ink

FLEXAQUAPAP by UFlex Chemicals Business is a revolutionary Sustainable Packaging Example that introduces water-based inks specifically formulated for food wraps and other flexible packaging.

Unlike conventional solvent-based inks, FLEXAQUAPAP utilizes water as a primary solvent, significantly reducing the emission of harmful volatile organic compounds (VOCs) during the printing process.

This makes the inks safer for the environment and for food contact applications, meeting stringent safety standards for packaging.

The FLEXAQUAPAP inks provide excellent print quality, vibrancy, and durability while being fully compliant with global food safety regulations.

They are specially designed to adhere well to paper-based and other substrates used in food wraps, enhancing the overall sustainability of the packaging.

By replacing traditional inks with water-based alternatives, UFlex is helping the packaging industry move towards greener, safer, and more eco-friendly printing solutions.

This innovation aligns with global sustainability goals, reducing the environmental footprint of packaging and promoting healthier, safer food packaging solutions.

49. Water-Soluble PVA Bag

PVA (Polyvinyl Alcohol) Bags for laundry cloths are a crucial Sustainable Packaging Example that gained significant importance during the COVID-19 pandemic, particularly in hospitals.

These innovative bags dissolve completely in water, allowing contaminated hospital laundry to be safely washed without any direct handling.

By preventing contact with potentially infectious materials or clothes, PVA bags provide an extra layer of protection for healthcare workers, reducing the risk of cross-contamination and the spread of viruses.

The bags are biodegradable and leave no toxic residues, aligning with environmental sustainability goals while enhancing safety.

During the pandemic, hospitals widely adopted PVA bags for handling infected bed linen, patients’ clothes or other fabric materials. It offers a secure and eco-friendly solution that minimizes exposure to hazardous bacteria, pathogens or viruses.

This innovation not only improved infection control measures but also demonstrated how sustainable materials could support critical healthcare needs, reinforcing the value of innovative, protective packaging in maintaining safety standards during public health crises.

Industry-Specific Packaging Innovation

50. Grass Paper Packaging

Grass Paper Packaging by Creapaper is an innovative and sustainable packaging solution that uses grass fibers as an alternative to traditional wood pulp.

The packaging is made from sun-dried grass combined with minimal wood pulp, which drastically reduces the need for water, chemicals, and energy typically used in paper production.

The grass is sourced from meadows that are not suitable for food production, ensuring it doesn’t compete with agricultural land.

How Grass Paper Helps to Reduce Environmental Damage?

1. Lower Resource Consumption: Grass Paper production consumes up to 75% less water and significantly fewer chemicals compared to conventional wood pulp paper. This reduces the environmental footprint of paper manufacturing and conserves vital natural resources.

2. Reduced Carbon Emissions: The production process of grass paper emits up to 50% less CO2 compared to traditional paper manufacturing. The low energy requirements and proximity of grass sources to production facilities further minimize transportation emissions.

3. Biodiversity Protection: By utilizing grass from non-arable land, this packaging option does not disrupt agricultural activities or deforest natural habitats, preserving ecosystems and biodiversity.

4. Renewable and Compostable: Grass is a highly renewable resource with rapid growth cycles. Grass Paper Packaging is fully recyclable and compostable, contributing to the circular economy by reducing waste and ensuring that packaging materials return safely to the environment.

Creapaper’s Grass Paper Packaging is an excellent example of how innovative use of natural resources can significantly reduce environmental impact, offering a sustainable alternative to conventional packaging solutions.

51. Fish Scale Bioplastic

MarinaTex, a UK-based company, has developed an innovative Sustainable Packaging Example by creating bioplastic from fish scales and skin, waste products from the fishing industry.

This unique bioplastic is a biodegradable, compostable, and environmentally friendly alternative to conventional plastic.

The material is flexible, strong, and translucent, making it ideal for single-use packaging such as bags, wrappers, and other food-related applications.

How Fish Scale Bioplastic Helps to Reduce Environmental Damage?

1. Utilizes Waste Materials: MarinaTex repurposes fish processing waste that would otherwise end up in landfills, reducing environmental pollution and making use of a readily available, sustainable resource.

2. Biodegradable and Compostable: Unlike conventional plastics, which can take hundreds of years to degrade, MarinaTex bioplastic decomposes naturally within four to six weeks, leaving no harmful residues and reducing the burden on landfills and marine environments.

3. Low-Carbon Production: The production of this bioplastic uses less energy compared to traditional plastic manufacturing processes, resulting in a lower carbon footprint. The process also avoids the use of fossil fuels, aligning with global efforts to reduce greenhouse gas emissions.

4. Plastic Pollution Reduction: By providing a biodegradable alternative to conventional plastics, MarinaTex helps to combat plastic pollution, particularly in oceans, where plastic waste poses a significant threat to marine life.

This sustainable innovation not only addresses the critical issue of plastic pollution but also highlights the potential of using waste as a valuable resource, contributing to a circular economy and fostering a cleaner environment.

What are the criteria that make packaging sustainable?

The key criteria that make packaging sustainable are centered around minimizing environmental impact and promoting the efficient use of resources.

Here’s a breakdown of the essential criteria:

1. Reduced Usage of Resources

Material Optimization: Using less materials in the packaging design without compromising functionality.

Renewable Resources: Prioritizing materials that are renewable or derived from sustainably managed sources, such as plant-based plastics or paper from FSC certified forests.

Minimal Use of Raw Materials: Reducing the dependency on virgin materials by using recycled or upcycled materials.

Material Efficiency: Using less material or lightweight alternatives for packaging reduces the energy required for production and transportation, thereby lowering carbon emissions.

For example, switching from heavy glass bottles to lightweight recycled plastic or paper can significantly cut-down carbon emissions during transportation.

2. Lower Carbon Emissions

Energy-Efficient Manufacturing: Utilizing production processes that require less energy, ideally powered by renewable sources like solar or wind energy.

Lightweight Design: Creating packaging that is lighter in weight to reduce transportation-related carbon emissions.

3. Recyclability

Ease of Recycling: Designing packaging that can be easily separated into recyclable components, with clear labeling to guide consumers.

High-Quality Recyclable Materials: Using materials that can be recycled multiple times without degrading in quality, such as aluminum or certain plastics.

4. Biodegradability and Compostability

Biodegradable Materials: Ensuring that the packaging can naturally break down in the environment without leaving harmful residues.

Compostability: Designing packaging that can be composted and turning into nutrient-rich compost under the right conditions.

5. Reusability

Multiple Use Cycles: Creating packaging that can be reused multiple times, reducing the need for single-use packaging.

Durability: Ensuring that the packaging is robust enough to withstand repeated use.

6. Minimal Environmental Impact

Non-Toxic Materials: Avoiding the use of hazardous chemicals or materials that can harm the environment or human health.

Reduced Waste: Designing packaging that minimizes waste during production and disposal, aiming for zero waste where possible.

7. Supporting Circular Economy

Material Recovery: Facilitating the recovery and reuse of materials in new products, keeping them in the economic loop.

Closed-Loop Systems: Encouraging systems where packaging is returned, refilled, or repurposed, rather than discarded after a single use.

By adhering to these criteria, packaging can significantly reduce its environmental footprint, contributing to a more sustainable future.

Benefits of Sustainable Packaging

Sustainable packaging offers numerous benefits that positively impact the environment, businesses, and consumers. By adopting sustainable packaging examples, companies can contribute to a healthier planet and enhance their brand reputation. Here are the key benefits:

1. Reduces Environmental Impact

Sustainable packaging examples, such as biodegradable, compostable, or recyclable materials, helps to reduce the environmental footprint of packaging waste.

By minimizing plastic use and promoting materials that decompose naturally or can be reused, sustainable packaging reduces pollution and conserves resources.

2. Supports a Circular Economy

Sustainable packaging is designed to be part of a circular economy where materials are kept in use for as long as possible.

Examples include packaging made from recycled content, like post-consumer recycled plastics or paper, which can be continuously reused, reducing the need for virgin materials.

3. Lowers Carbon Footprint

By using renewable resources, reducing packaging weight, and optimizing logistics, sustainable packaging helps to lower greenhouse gas emissions.

For instance, lightweight packaging examples, such as Frugalpac’s Paperboard Bottle for Wine, uses less energy during transportation and cutting down carbon emissions.

4. Enhances Brand Image and Consumer Trust

Consumers are increasingly choosing brands that prioritize sustainability.

Companies that adopt sustainable packaging examples, like MarinaTex’s Fish Scale Bioplastic, appeal to eco-conscious consumers, enhancing brand loyalty and demonstrating a commitment to environmental stewardship.

5. Improves Product Safety and Health

Sustainable packaging often avoids toxic chemicals, such as BPA and phthalates, found in traditional plastics.

Water-based inks and natural adhesives used in packaging examples like UFlex’s FLEXAQUAPAP ensure products are safer for both consumers and the environment.

6. Reduces Waste and Promotes Recycling

Sustainable packaging examples, such as K3® r100 – Self-Separating Cup by Greiner Packaging, are designed for easy recycling, helping to reduce the amount of waste that ends up in landfills.

These designs simplify waste management and encourage consumers to recycle properly.

7. Cost Savings in the Long Term

Although initial investments in sustainable packaging might be higher, the long-term savings from reduced waste, lower material costs, and improved logistics can be significant.

Efficient designs and the use of readily available renewable materials contribute to cost efficiency.

8. Compliance with Regulations

Many regions are imposing stricter regulations on plastic usage and waste management.

Adopting sustainable packaging examples helps to businesses stay ahead of regulatory requirements, avoiding fines and ensuring compliance with environmental standards.

9. Supports Innovation and Competitive Advantage

Sustainable packaging drives innovation, allowing companies to differentiate themselves in the market.

Examples like PulPac’s Dry Molded Fiber showcase how innovative packaging solutions can meet functional needs while minimizing environmental impact.

Overall, sustainable packaging not only contributes to environmental preservation but also enhances business operations, consumer satisfaction, and market competitiveness.

Challenges of Sustainable Packaging

Sustainable packaging offers significant environmental benefits, but its implementation comes with several challenges that businesses and industries must navigate:

1. Higher Initial Costs

One of the primary challenges of adopting sustainable packaging is the higher upfront costs associated with eco-friendly materials and technologies.

Biodegradable or compostable materials, such as PLA or plant-based plastics, often cost more than conventional plastics, making it financially challenging for companies, especially small businesses, to switch.

2. Material Availability and Scalability

Sustainable packaging relies on renewable resources, which may not always be available in large quantities or at competitive prices.

For example, materials like seaweed, hemp, or mycelium are innovative but can be difficult to scale up for mass production, limiting their use in larger operations.

3. Performance and Durability Issues

Many sustainable packaging materials, such as paper or bioplastics, may not perform as well as traditional plastics, especially in terms of moisture resistance, strength, and shelf life.

This can be problematic for products that require robust packaging to ensure product safety and integrity.

4. Complex Recycling Infrastructure

Not all sustainable packaging can be easily recycled in existing waste management systems.

For example, compostable packaging often requires industrial composting facilities that are not widely available, and multi-material packages like those combining plastic and paper can be challenging to separate and recycle properly.

5. Consumer Misunderstanding

There is often confusion among consumers about how to properly dispose of sustainable packaging, leading to contamination in recycling streams.

Labels such as “compostable” or “biodegradable” can be misleading if not accompanied by clear disposal instructions, resulting in improper waste management.

6. Supply Chain Adjustments

Implementing sustainable packaging often requires adjustments throughout the supply chain, from sourcing raw materials to redesigning packaging machinery.

These changes can be time-consuming, costly, and require retraining staff, which can slow down the transition to more sustainable practices.

7. Regulatory Challenges

Regulations around sustainable packaging can vary widely across regions, creating challenges for companies operating internationally.

Ensuring that packaging meets varying local regulations, such as those related to recyclability or chemical safety, can be complex and costly.

8. Limited Consumer Acceptance

Some consumers may be resistant to sustainable packaging due to perceived differences in quality or functionality compared to traditional packaging.

Convincing consumers to adopt new packaging types requires education and marketing efforts, which can be an additional challenge for brands.

9. Innovation Lag in Specific Sectors

While some industries, like food and beverages, have seen rapid advancements in sustainable packaging, others, such as pharmaceuticals or electronics, face more stringent requirements that make the adoption of eco-friendly materials more difficult.

Addressing these challenges requires continued innovation, investment, and collaboration across industries to improve sustainable packaging solutions and make them accessible and effective on a global scale.

Conclusion

Sustainable packaging plays a crucial role in the global shift towards more environmentally responsible consumption and production. It offers significant benefits, such as reducing environmental impact, supporting a circular economy, and enhancing brand image, while also providing consumers with safer and eco-friendly options. However, the journey toward fully sustainable packaging is not without its challenges, including higher costs, performance limitations, complex recycling processes, and the need for industry-wide adjustments.

Despite these obstacles, continued innovation and investment in sustainable packaging solutions are essential. Companies, governments, and consumers must collaborate to address these challenges, improve recycling infrastructures, and educate the public on proper disposal methods. As more businesses adopt sustainable packaging examples, such as compostable bioplastics, recyclable paper-based alternatives, and renewable resource packaging, the positive impact on the environment will grow, driving a more sustainable future. Embracing sustainable packaging is not just a trend but a necessary step towards preserving our planet for future generations.