Biodegradable corn starch packaging refers to packaging materials that are derived from corn starch. Corn starch is derived from the endosperm of corn kernels and is categorized as a carbohydrate.

Food industries are taking remarkable steps in accepting biodegradable cornstarch packaging.

This plant based packaging polymer represent a developing segment of bioplastics and their productions and usages are increasing day by day.

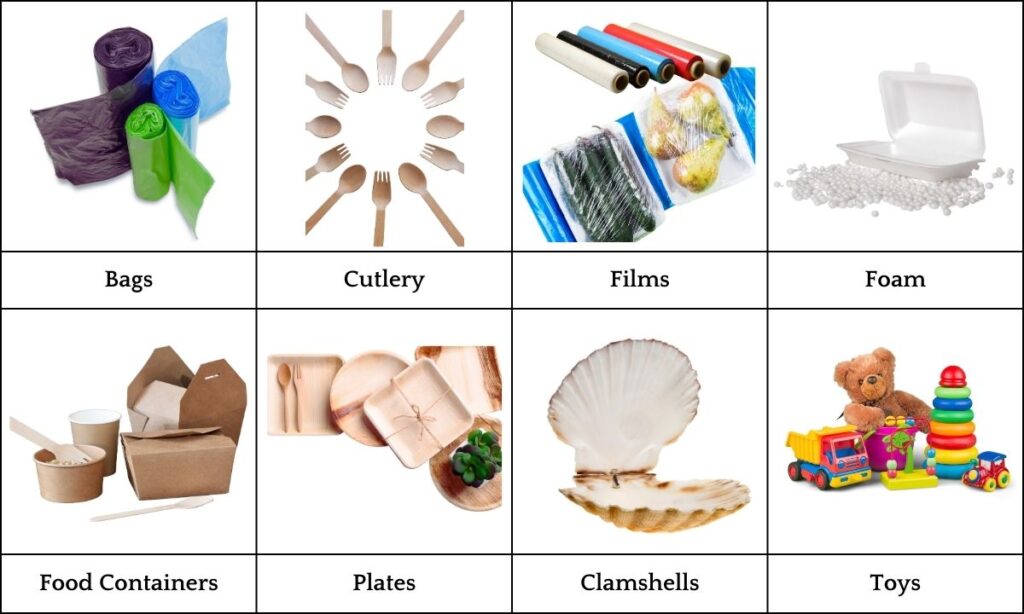

Corn starch packaging is used now in pharma industries, food industries, textiles industries, hospitality, e-commerce packaging, toys and fashion industries.

Non-biodegradable plastics, which are known by a their long and strong polymer chain, are widely used for various applications because of their mechanical and barrier properties.

Worldwide production of non-biodegradable plastics is increasing continuously and reach up to 1000 million tons by 2050.

Despite the remarkable contribution of petroleum-based plastics, non-degradable nature of this polymer represents an environmental issue, such as global warming and climate change.

Starch has best linking capacity with filler. So resulting starch based polymer have desirable mechanical and barrier properties.

Moreover, due to availability and cost point of view, corn starch packaging is the best choice for all industries.

Corn starch packaging material, also known as bioplastic or biodegradable plastic, is a type of packaging material made from corn starch, which is a renewable resource. It is derived from the starch in corn kernels through a process called polymerization.

This material is biodegradable, meaning it can be broken down by microorganisms in the environment, unlike traditional plastics which can persist for hundreds of years.

Overall, corn starch packaging represents a more sustainable alternative to petroleum-based plastic packaging, contributing to efforts to reduce plastic pollution and minimize environmental impact.

An alternative to non-biodegradable polymer is necessary because non-biodegradable polymers, such as traditional plastics, can persist in the environment for hundreds of years, contributing to pollution and environmental degradation.

Biodegradable polymers break down more quickly and naturally, reducing the long-term impact on ecosystems, wildlife and human health.

Developing alternatives to non-biodegradable polymer is essential for sustainable waste management and mitigating the environmental consequences of plastic pollution.

Cornplastic is typically composed of polylactic acid (PLA), a biodegradable and compostable thermoplastic derived from fermented plant sugars, usually extracted from cornstarch.

The manufacturing process of corn starch polymer involves several steps.

Corn Harvesting: The process begins with the cultivation and harvesting of corn.

Corn is a renewable resource and its cultivation is more sustainable compared to fossil fuel-based resources or petroleum based resources used in traditional plastic production.

Corn Milling: The harvested corn is milled to separate the starch from other components such as proteins and fibers.

This milling process produces cornstarch, which serves as the primary raw material for corn starch plastic and later can be used in bio based packaging.

Fermentation: The extracted cornstarch undergoes a fermentation process.

During fermentation, bacteria break down the starch molecules into lactic acid. This lactic acid is the precursor for the production of PLA (Polylactic Acid).

Lactic Acid Production: The lactic acid is then isolated and undergoes further processing of polymerization to create polylactic acid (PLA).

This polymerization process transforms the lactic acid into a biodegradable and compostable polymer.

Polymerization: PLA is polymerized to create the long chains necessary for forming a bio-based polymer.

This step involves linking the individual lactic acid molecules together to form a stable and durable bio-based polymer.

Extrusion and Shaping: The PLA (Polylactic Acid) is melted and extruded into the desired shape of plastic article for sustainable packaging.

This can include sheets, films or molded shapes depending on the intended application.

Cooling and Solidification: The shaped PLA (Polylactic Acid) undergoes a cooling and solidification process to give it its final structure.

This may involve passing the material through rollers or other cooling mechanisms.

Cutting and Forming: The cooled and solidified PLA plastic is cut and formed into the specific renewable packaging products, such as bags, containers, or utensils.

Composting cornstarch packaging materials in industries involves several steps to ensure efficient decomposition and environmental sustainability.

1. Separation: Separate corn starch plastics from other waste materials to ensure purity and facilitate the composting process.

2. Shredding: If the corn starch packaging material is in large pieces, it is beneficial to shred or break it down into smaller pieces. This increases the surface area for microbial activity and accelerate the decomposition process.

3. Mixing: Blend the shredded corn starch plastic material with other organic materials like food waste, garden trimmings, or compostable plastics. This helps to balance the carbon-to-nitrogen ratio and enhances the overall composting process.

4. Aeration: Maintain proper aeration within the compost pile or vessel to promote aerobic decomposition. Turning or mixing the compost regularly helps to introduce oxygen and prevent anaerobic conditions, which can lead to unpleasant odors.

5. Humidity or Moisture Management: Ensure the compost pile maintains adequate moisture levels, like a wrung-out sponge. Too much water can cause anaerobic conditions, while too little can slow down decomposition. Ensure optimum moisture level regularly for fast and effective composting.

6. Temperature Monitoring: Monitor the internal temperature of the compost pile using a compost thermometer. Ideal temperatures for composting typically range between 110°F and 160°F (43°C to 71°C). These temperatures support the activity of thermophilic microorganisms, which is responsible for breaking down organic matter.

7. Time and Monitoring: Allow sufficient time to complete composting process. The duration can vary depending on various factors, such as temperature, moisture, composting enzymes and the size of the compost pile. Monitor compost regularly for the signs of maturity, such as a dark, crumbly texture and an earthy smell.

8. Testing and Quality Assurance: Conduct periodic testing to ensure the finished compost meets quality standards and is free from contaminants. This may involve soil testing for nutrient content, pH levels, and the presence of pathogens or heavy metals.

By following these steps, industries can effectively compost corn starch packaging materials, diverting organic waste from landfills, and contributing to a more sustainable waste management system.

To ensure the biodegradability and compostability of corn starch-based plastic, several standardized tests and criteria are typically performed and assessed.

These tests evaluate how well the material breaks down in natural or composting environments, as well as the potential environmental impact. Here’s a summary of key tests and standards:

1. Biodegradability Tests

These tests measure how well corn starch plastic decomposes by microbial activity into natural substances like carbon dioxide, water, and biomass. Standards include:

ISO 14855 (Determination of the Ultimate Aerobic Biodegradability of Plastic Materials): Measures the breakdown of plastic under controlled composting conditions, tracking CO₂ evolution.

ASTM D5988 (Standard Test Method for Determining Aerobic Biodegradation in Soil): Measures biodegradation in a soil environment by tracking the CO₂ released.

ISO 16929 / ASTM D5338 (Aerobic Biodegradation in Composting Conditions): Determines the biodegradability of plastics in a composting environment under aerobic conditions.

ISO 20200 (Plastic Disintegration in a Composting Environment): Determines the physical disintegration of the plastic in controlled composting conditions by assessing fragment size after a specified time.

EN 14806 / ASTM D6400: These standards also check if the plastic disintegrates into small enough pieces within the composting process, such that no visible fragments remain after a defined period.

Compostability tests assess whether the material can break down in a compost environment without leaving toxic residues.

ASTM D6400 / EN 13432 (Compostable Plastics Standard): These comprehensive standards ensure that the plastic breaks down in composting conditions, leaves no toxic residue, and does not harm plant growth.

Biodegradation: 90% biodegradation within 180 days under industrial composting conditions.

Disintegration: The material should disintegrate and pass through a 2mm sieve after 12 weeks.

Toxicity Testing: Compost produced should be non-toxic and promote healthy plant growth.

These tests evaluate whether the breakdown products of the plastic have any negative impact on the environment, plants, or microorganisms.

OECD 208 (Terrestrial Plants Test): Assesses the effects of the plastic’s decomposition products on seed germination and plant growth.

OECD 207 (Earthworm Toxicity Test): Evaluates the toxicity of the degradation by-products on soil organisms like earthworms.

5. Heavy Metal and Residual Testing

EN 13432 / ASTM D6400: Require tests for the presence of heavy metals or other harmful substances to ensure that the compost or soil remains safe for use. This ensures the composted material does not release harmful substances during degradation.

These tests ensure that corn starch-based plastics meet international standards for biodegradability and compostability, making them environmentally friendly alternatives to conventional plastics.

Corn starch is often used to produce biodegradable and environmentally friendly packaging materials.

One common example is biodegradable polymer made from corn starch, known as polylactic acid (PLA). PLA is a type of biopolymer that is derived from renewable resources, such as corn starch or sugarcane.

Here are some examples of corn starch-based packaging.

The cost of corn starch packaging can vary based on several factors, including the type of packaging, the manufacturing process, the scale of production, and market conditions.

Here are some factors that can influence the cost of corn starch packaging:

By incorporating compostable bags into your daily routine, you’re making a small yet significant step towards a greener future, where every action counts in preserving our planet for future generations.

With rising awareness of sustainable packaging, many counterfeit “compostable” bags are circulating in the market.

These are often made from petroleum-based polyethylene (PE) mixed with oxo-degradable additives, which degrade upon oxidation but ultimately turn into harmful microplastics.

Despite being labeled as biodegradable, they are not truly compostable and are an example of greenwashing—misleading consumers with false sustainability claims.

To verify if a bag is genuinely compostable, you can perform a dichloromethane (DCM) test.

By using corn starch cutlery, you’re making a conscious choice to protect our oceans and wildlife from the harmful effects of plastic pollution, contributing to a cleaner and healthier planet.

Corn starch packaging offers several environmental benefits, making it a more green alternative to traditional plastics.

Natural Decomposition: Corn starch plastic is biodegradable and can be broken down by microorganisms into simple compounds.

Reduction in Plastic Pollution: Unlike traditional plastics that persist in the environment for hundreds of years, corn starch based plastics breaks down into non-toxic components in few weeks.

Plant-Based Polymer: Corn starch is derived from corn, which is a renewable resource that can be replenished through agricultural practices.

3. Reduced Carbon Footprint

Lower Energy Intensity: The production of corn starch-based packaging generally requires less energy as compared to petroleum based plastic production.

Carbon Sequestration: The cultivation of corn plants contributes to carbon sequestration through photosynthesis.

Contribution to Soil Health: Corn starch packaging is often compostable and can be added to compost bins along with organic waste.

In appropriate composting conditions, it breaks down into compost, enriching the soil with organic matter.

Reduced Landfill Waste: Compostable materials like corn starch packaging, reduce the amount of waste sent to landfills, where traditional plastics can persist for long periods without breaking down.

5. Reduced Dependency on Fossil Fuels

Alternative to Petroleum based Plastics: Corn starch provides a green alternative to plastics derived from fossil fuels, helping to decrease dependency on non-renewable resources like coal, oil and gas.

Mitigation of Climate Change: By using renewable resources like corn, the production of corn starch packaging contributes to mitigate global warming and climate change.

6. Support for Circular Economy

Closed-Loop Life Cycle: Corn starch packaging follows a closed-loop life cycle, aligning with the principles of a circular economy.

It can be derived from plants, used and then returned to the environment through composting.

In summary, corn starch packaging stands out as a renewable, compostable, biodegradable, sustainable, green and resource-efficient alternative to non-biodegradable plastics.

Corn starch packaging has a versatile range of applications and uses. It is the best green alternatives for traditional plastic packaging materials.

Disposable Plate: Corn starch packaging is used to prepare food dishes or takeout containers.

Food Packaging: This compostable packaging can be used for food products, such as snacks, fresh produce and baked goods.

2. Retail and Consumer Goods

Packaging Materials: Corn starch-based materials can be used in various retail packaging applications, such as blister packs, trays and bags.

Electronics Packaging: Sustainable and eco-friendly packaging solutions for electronic products, such as protective cushioning and trays.

3. Cosmetics and Personal Care

Beauty Product Packaging: Corn starch packaging can be used for cosmetics and personal care products, such as containers for creams, powders and lotions.

Toiletry Packaging: This natural polymer packaging for toiletry items such as soap, shampoo and toothpaste.

4. Pharmaceutical Industry

Medicine Packaging: Corn starch-based materials can be used for pharmaceutical packaging, providing an eco-friendly alternative to non-biodegradable plastic bags, bottles and blister packs.

Seed Packaging: This plant-based packaging can be used for seed packaging, providing a sustainable option for agricultural products.

Fertilizer Packaging: Sustainable packaging for fertilizers and other agricultural inputs.

6. E-commerce and Shipping

Shipping Materials: Corn starch-based materials can be used for protective packaging materials, such as cushioning and void fill.

Hotel Amenities: Corn starch packaging can be used for single-use amenities in hotels, such as cups, cutlery and toiletry packaging.

Automotive Parts Packaging: Environmental friendly packaging solutions for automotive parts and components, reducing the environmental impact of packaging materials in the automotive sector.

Disposable Tableware: Corn starch-based plates, cups and cutlery can be used for catering events, festivals and outdoor gatherings, offering a best sustainable option for single-use items.

Corn starch packaging’s biodegradability, compostable and renewable nature make it suitable for a wide range of applications.

While corn starch packaging presents several environmental benefits and prominent alternative option for traditional plastic that doesn’t mean that it is an optimal solution for current environmental issues.

It require a proper disposal and composting facilities for fully degradation.

Corn starch-based packaging materials can be more expensive to produce as compared to conventional plastic packaging materials.

However, advancements in technology and increased demand may contribute to reduce cost over time.

2. Agricultural Practices

The production of corn starch depend on agricultural practices and problem may arise regarding land use, water consumption and potential impacts on biodiversity.

3. Resource Competition with Food Supply

There is a concern that using corn for packaging may contribute to resource competition with food production, potentially affecting food prices and availability.

4. Limited Composting Facilities

The efficient biodegradation of corn starch packaging depend on proper composting conditions.

5. Home Composting Challenges

Corn starch packaging designed for industrial composting may not break down as effectively in home composting, where conditions are less controlled.

6. Functional Limitations

Corn starch packaging may have limitations in terms of durability, heat resistance and moisture resistance compared to petroleum based plastics.

To Meet the growing demand for sustainable packaging materials like corn starch based polymer on a large scale may create problem for higher production, infrastructure and supply chain logistics.

8. Proper Disposal Education

Complete biodegradation and compostability require proper disposal practices and facilities.

The regulations for biodegradable and compostable materials is evolving. Changes in regulations may impact the acceptance and use of corn starch packaging in different regions and countries.

10. Material Integrity and Contamination

Contamination from non-biodegradable materials in the manufacturing process can affect the overall integrity of corn starch packaging and its biodegradability.

The field of corn starch packaging technology continues to evolve with ongoing research and development to improve its performance, versatility and environmental impact.

1. Enhanced Durability and Barrier Properties

Researchers are exploring to enhance the mechanical strength, flexibility and barrier properties of corn starch-based materials.

Cross-linking agents like glyoxal, epichlorohydrin or other suitable compounds can be added to enhance durability.

Additives like clay nanoparticles, chitosan or other biodegradable polymers can be added to enhance barrier properties.

2. Functional Additives and Blends

Incorporating various additives and blending corn starch with other materials to achieve specific functional properties.

This may include reinforcements with natural fibers or the addition of nanomaterials to enhance performance characteristics.

3. Improved Heat Resistance

Researchers are exploring different methods to enhance the material’s ability to withstand higher temperatures, making it suitable for a broader range of applications, including hot-fill packaging.

Mix corn starch paste with high-heat polymers such as polyhydroxyalkanoates (PHA), or polyethylene terephthalate (PET).

4. Nanotechnology in Corn Starch Packaging

Nanoparticles and nanocomposites can be incorporated to enhance material properties like strength and additional functionalities.

Utilizing bio-based coatings on corn starch packaging can enhance its performance and extend its shelf life.

These coatings may offer improved moisture resistance, gas barrier properties and overall stability.

6. Improved Water Resistance

Starch esterification involves reacting starch with fatty acids or anhydrides, forming hydrophobic starch esters. This process can improve water resistance.

By adding hydrophobic materials, such as waxes or lipid-based substances, can enhance water resistance. These additives form a barrier that repels water.

Incorporating other biopolymers like chitosan or alginate can improve the water resistance of starch-based materials.

7. Biodegradation Accelerators

Researchers are exploring additives or treatments that can accelerate the biodegradation process of corn starch packaging.

Addition of amylase enzymes that can break down starch into simpler sugars. Adding microbial cultures, such as bacteria or fungi that are capable of breaking down starch.

8. Smart Packaging Applications

Integration of smart packaging features with corn starch-based materials is a potential innovation.

This may include incorporating sensors or indicators for freshness, temperature monitoring, or product authentication.

9. Scale-Up and Cost Reduction

Advancements in manufacturing processes, optimization of raw material sourcing, and economies of scale could contribute to cost competitiveness.

Developing technologies for the valorization of waste streams, such as agricultural by-products or post-consumer corn starch packaging, can contribute to a more circular and sustainable approach to the entire life cycle of these materials

11. Biocompatible and Medical Applications

Innovations in corn starch packaging technology may open up possibilities for biocompatible materials suitable for medical and healthcare applications, such as surgical implants or controlled drug release systems.

12. 3D Printing for Sustainable Packaging

3D printing technologies are being investigated for creating customizable, low-waste packaging solutions.

The use of biodegradable and recyclable materials in 3D printing aligns with sustainability goals.

These potential developments represent the ongoing commitment to improving the properties and applications of corn starch-based packaging materials, making them more competitive and sustainable alternatives in various industries.

There are several companies around the world that are noticeable for their production of biodegradable packaging materials, including those made from corn starch. Some of these companies include:

BASF is a global chemical company that produces a variety of biodegradable plastics, including those derived from renewable resources such as corn starch. They offer solutions for packaging applications as well as other industries.

Novamont specializes in the development and production of bioplastics and biodegradable polymers. They offer products such as Mater-Bi, a biopolymer derived from corn starch and other renewable sources, used in packaging, agriculture, and more.

4. Mitsubishi Chemical Corporation (Japan)

Mitsubishi Chemical produces a range of biodegradable plastics, including those based on corn starch. Their products are used in various applications, including packaging and agricultural films.

5. Biome Bioplastics (UK)

Biome Bioplastics is a manufacturer of biodegradable and compostable plastics, including materials derived from corn starch. They offer customizable solutions for packaging, food service, and other applications.

In view of the advantages and disadvantages of corn starch packaging, it becomes very clear that this eco-friendly alternative holds significant promise for a sustainable future.

Despite facing main challenges such as cost and moisture sensitivity, the benefits in terms of biodegradability, compostability, reduced environmental impact and renewable resource will help to mitigate global warming and climate change.

As we conclude our exploration, let’s accept the potential of corn starch packaging as a pivotal step towards a greener future.

By understanding and addressing its limitations, we can maximize the positive impact of this green and innovative solution and contribute to a world where packaging not only protects our products but also save our planet.

Pingback: Understanding of Climate Change