Yes, PLA plastic (Polylactic Acid) is generally considered food safe. Made from renewable, plant-based materials like corn starch and sugarcane, PLA is non-toxic and biodegradable. It does not leach harmful chemicals into food under normal usage conditions, making it a safe alternative to petroleum-based plastics. The FDA (Food and Drug Administration) has approved PLA for food applications.

Introduction

In today’s world, where protecting the environment is more important than ever, people are looking for better alternatives to traditional plastics.

One such innovative solution is PLA plastic, a material designed to be more eco-friendly and sustainable.

PLA, or Polylactic Acid, is a biodegradable plastic made from plant based materials such as corn starch or sugarcane.

Unlike conventional plastics derived from petroleum, PLA plastics offers an eco-friendly solution with the potential to reduce our dependency on non-renewable resources.

When PLA plastic comes in contact with the food packaging, safety is very important.

We often use plastic food containers, utensils, and wraps daily without considering whether the materials are safe for our health or not.

PLA plastic has gained attention because of its sustainability nature, but questions remain about its safety to use in food packaging.

Can it handle different temperatures without breaking down?

Does it release harmful chemicals?

Governments, businesses, and consumers worldwide are promoting PLA plastics for greener alternatives to reduce plastic pollution.

In this blog post, we’ll explore the science behind PLA, its benefits, and whether it is truly a safe material for food contact or not.

What is PLA Plastic?

PLA, or Polylactic Acid, is a type of biodegradable plastic made from renewable resources like corn starch, sugarcane, or cassava.

Unlike traditional plastics, which are derived from petroleum, PLA comes from natural, plant-based materials.

This makes it an eco-friendly alternative to conventional plastics, as it reduces our reliance on fossil fuels and has a lower environmental footprint or carbon emission.

One of the standout features of PLA plastic is its biodegradability and Compostability.

Under the right industrial composting conditions (Temperature & Humidity), PLA plastic decomposes into carbon dioxide, water, and organic matter, leaving behind no toxic residues. This can be used to improve soil health by using as an organic fertilizer.

This property makes PLA plastic an attractive option for single-use items like food containers, disposable utensils, and packaging materials.

In addition to its biodegradability, PLA is lightweight and versatile, making it easy to mold into various shapes and sizes.

It can be used to create cups, plates, straws, plastic containers, and even clear film for food wrapping.

Its transparent and glossy finish also gives it a visually appealing look, similar to traditional plastics like PET.

When compared to conventional plastics, PLA offers significant environmental benefits.

Traditional plastics take hundreds of years to decompose into micro/nano-plastic and often release harmful chemicals into the environment.

PLA, on the other hand, decomposes much faster in industrial composting facilities.

However, it has some limitations, such as being less heat-resistant and requiring specific conditions for biodegradation.

Refer our comprehensive blog post: Biodegradable Corn Starch Packaging.

How is PLA Plastic Used in Food Packaging?

PLA plastic has found a prominent place in the food packaging industry, offering an eco-friendly alternative to traditional plastic products.

Its versatility, lightweight, non-toxic, and biodegradable nature make it an ideal choice for a variety of applications.

Common Uses of PLA plastics in Food Packaging

Cups: PLA-based coffee cups and cold beverage cups are common at eco-conscious cafés. These cups are durable enough to hold liquids while being compostable after use.

Plates and Bowls: Disposable PLA plates and bowls are a popular choice at events and restaurants looking to reduce their environmental impact.

Utensils: PLA is molded into forks, spoons, and knives, providing biodegradable cutlery for picnics, takeaways, and catering services.

Food Containers: Transparent PLA containers are often used for salads, fruits, and other ready-to-eat meals. Their clear design makes them visually appealing, while their compostable nature appeals to environmentally conscious consumers.

Advantages for the Food Industry

Eco-Friendly Alternative: PLA helps to reduce the reliance on petroleum-based plastics, offering a sustainable solution for single-use packaging.

Compostable Nature: Unlike conventional plastics that persist in the environment for centuries, PLA products can decompose in industrial composting facilities, turning into organic matter within weeks for sustainable agriculture.

Safe for Food Contact: PLA is FDA-approved food-grade material, ensuring it does not leach harmful chemicals when in contact with food, pharma and cosmetic packaging.

Brand Value: Businesses using PLA products showcase their commitment to sustainability, appealing to eco-conscious customers.

Real-Life Examples of PLA-Based Products

Starbucks and PLA Coffee Lids: Starbucks has tested PLA-based lids as part of their strategy to phase out single-use plastics, providing customers with an environmentally friendly way to enjoy their drinks.

Eco-Friendly Meal Kits: Popular meal delivery services like HelloFresh and Blue Apron often use PLA containers for fresh produce or pre-cooked meals, reducing their packaging waste.

Event Catering: Music festivals and large-scale events have started switching to PLA containers, plates, cups, and cutlery to minimize the environmental footprint created by thousands of attendee.

PLA Water Bottles: Brands like VIVA and BIOTA have introduced water bottles made entirely of PLA plastic, offering a compostable alternative to traditional plastic bottles.

Imagine ordering a fresh food or salad from your favorite restaurant and receiving it in a crystal-clear PLA container, paired with a compostable fork and knife.

After enjoying your meal, you know that instead of adding to a landfill or oceans, the packaging waste can be composted to enrich the soil.

This seamless blend of functionality and environmental responsibility is precisely why PLA is gaining attention in the food packaging industry.

The Science Behind PLA's Safety

When it comes to food safety, understanding the science behind PLA (Polylactic Acid) is crucial.

Let’s dive into the details of its chemical composition, how it interacts with food, and what the research and regulations say about its safety.

Chemical Composition and Interaction with Food

PLA is made from plants like corn starch or sugarcane. Its main components are lactic acid molecules, which are polymerized to create a durable and versatile material.

Since it originates from plant-based material, PLA is inherently non-toxic and safe for use in food packaging.

When used for food contact, PLA plastic does not release harmful chemicals into the food since toxic additives like phthalates, BPA are not used in its manufacturing process.

Unlike petroleum-based plastics that often use harmful chemicals like phthalates, BPA, toxic fire retardants, and colorants to enhance their properties, PLA plastic is free from these additives, making it a safer and more eco-friendly choice.

Does PLA Plastic Leach Chemicals at High Temperatures?

One of the concerns with plastics, in general, is whether they leach chemicals when exposed to high temperatures.

PLA, being a biodegradable plastic, has a lower heat tolerance compared to traditional plastics.

At normal temperatures (room temperature or when used for cold food and drinks), PLA remains stable and does not release any chemicals.

At high temperatures (above 50°C or 122°F), PLA can start to soften or deform. This has led to questions about whether it leaches harmful substances into food. The good news is that studies show PLA is generally safe and does not release toxins, even under high temperatures.

However, PLA is not suitable for hot food items, such as coffee or soup, as it can degrade or deform under such conditions.

Studies and Research on PLA’s Food Contact Safety

Extensive research has been conducted to ensure PLA is safe for food packaging. Studies confirm that PLA:

• Does not release harmful chemicals during food contact.

• Maintains its chemical stability when in contact with acidic, oily, or aqueous foods.

For example, a study published in Food Additives & Contaminants analyzed PLA’s performance and concluded that it is safe for storing food and beverages when used appropriately.

Regulatory Approvals by Organizations

Globally, regulatory bodies have tested and approved PLA for food contact applications:

FDA (Food and Drug Administration, USA): PLA is recognized as a safe material for food-grade applications. This means it can be used for cups, plates, containers, and utensils without any safety concerns.

EFSA (European Food Safety Authority): PLA has been approved as a food-contact material in Europe, ensuring it meets the high standards for safety and health.

These approvals from trusted organizations provide confidence to manufacturers and consumers alike that PLA is a reliable and safe choice for food packaging.

Benefits of Using PLA Plastic in Food Packaging

PLA (Polylactic Acid) offers several benefits that make it an excellent choice for food packaging, especially in today’s eco-conscious world.

Eco-Friendly and Biodegradable

One of the biggest advantages of PLA plastic is its eco-friendly nature.

Unlike traditional plastics that take hundreds of years to decompose into microplastic or nano plastic, PLA is biodegradable under industrial composting conditions.

This means PLA plastic can decompose into natural components like carbon dioxide, water, and organic matter, leaving no toxic residues behind.

Using PLA for food packaging helps to reduce the long-term burden of plastic waste on the environment.

Reduces Dependency on Petroleum-Based Plastics

Traditional plastics are made from petroleum resource.

With increasing concerns about fossil fuel depletion and climate change, PLA plastic provides a sustainable alternative.

Since it is derived from renewable sources like corn starch or sugarcane, PLA plastic reduces our dependency on petroleum-based materials and contributes to a cleaner, greener future.

Supports Sustainable Practices in the Food Industry

The food industry plays a crucial role in shaping sustainability practices. By adopting PLA-based packaging, businesses can lower their environmental footprint and appeal to eco-conscious consumers.

PLA products, such as compostable containers, utensils, and wraps or films, align with the growing demand for sustainable packaging solutions, helping companies showcase their commitment to environmental responsibility.

In summary, PLA plastic not only addresses the challenges of plastic pollution but also supports the transition to a more sustainable and environmentally friendly food industry. It is a step towards creating a healthier planet for future generations.

Limitations of PLA plastic in Food Packaging

While PLA (Polylactic Acid) is a promising eco-friendly material, it does come with some limitations and challenges that are important to understand.

Temperature Sensitivity

PLA plastic has a lower heat resistance compared to traditional plastics.

It can soften or even melt at temperatures above 50°C (122°F), making it unsuitable for hot foods or beverages.

For example, using a PLA coffee cup for a hot drink may cause it to deform.

Challenges in Industrial Composting

PLA is marketed as compostable, but it requires specific industrial composting conditions to break down effectively.

These facilities provide high heat and controlled humidity along with few enzymes, which are not available in typical home composting setups.

This has led to misconceptions among consumers who believe PLA can be composted in their backyard.

When disposed of in regular trash or landfills, PLA does not degrade as intended, limiting its environmental benefits.

Potential for Chemical Contamination

While PLA itself is made from natural, plant-based materials, there is a risk of chemical contamination during production or decomposition.

For instance, additives or colorants used in manufacturing PLA products could introduce harmful chemicals.

Additionally, if PLA plastic is not processed correctly, it might leave behind microplastics or residues that could impact the environment.

Limited Lifespan Compared to Conventional Plastics

Unlike traditional plastics, which can last for decades, PLA has a relatively short lifespan.

It can degrade over time when exposed to sunlight, moisture, or heat.

While this is an advantage for reducing waste, it can also be a drawback for products requiring long-term durability.

Environmental and Ethical Considerations for PLA Plastic

PLA (Polylactic Acid) is often celebrated for its potential to reduce environmental damage caused by traditional plastics.

However, its impact on sustainability and ethics goes deeper than just its biodegradability.

Contribution to Reducing Plastic Pollution

One of PLA’s biggest advantages is its ability to address the global plastic pollution crisis.

Traditional plastics take hundreds of years to decompose, clogging landfills and harming wildlife. In contrast, PLA, when disposed of in industrial composting facilities, breaks down into organic matter within weeks for agricultural use.

By replacing single-use plastics like cups, plates, and packaging with PLA, we can significantly reduce non-biodegradable waste, helping to create cleaner oceans, landfills, and cities.

Role in Achieving a Circular Economy

PLA plastic aligns with the principles of a circular economy, where materials are reused, recycled, or composted rather than discarded.

Since PLA is derived from renewable resources like corn and sugarcane, its production supports a sustainable supply chain.

When composted properly, PLA can enrich the soil, completing a full life cycle that benefits the environment.

However, for this to work effectively, infrastructure for industrial composting needs to be widely available.

Ethical Debates Around Using Food Crops

While PLA plastic is a step toward sustainability, its reliance on food crops like corn and sugarcane raises ethical concerns.

These crops require large amounts of water, land, and fertilizers, which could otherwise be used to grow food for a growing global population.

Critics argue that using agricultural resources for plastic production may contribute to food insecurity and higher food prices in certain regions.

Balancing the demand for biodegradable plastics with the need to feed the world’s population is an ongoing ethical challenge.

Practical Tips for Consumers

Using PLA (Polylactic Acid) food-safe products can be a great way to reduce your environmental impact, but understanding how to use and dispose of them correctly is essential.

How to Identify PLA Food-Safe Products

Labels and Symbols: Look for terms like “compostable,” “biodegradable,” or “made from PLA” on the product packaging.

Many PLA products also have the number 7 inside a recycling triangle with “PLA” printed beneath it.

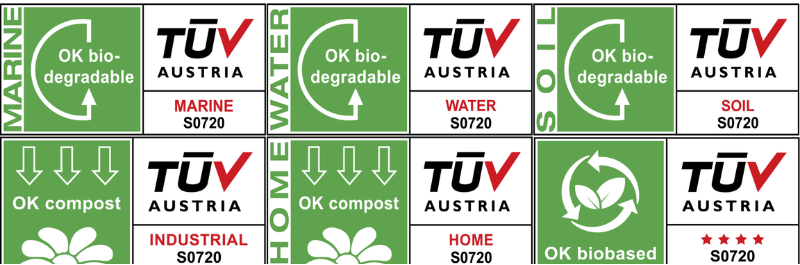

Certifications: Trusted certifications like BPI (Biodegradable Products Institute) or OK Compost ensure the product meets compostability standards and is safe for food contact.

Material Appearance: PLA often looks similar to clear plastic (like PET) but has a smoother, slightly glossier finish.

Using PLA Products Safely

Temperature Limits: PLA is best suited for cold or room-temperature foods and drinks. Avoid using it with hot liquids or foods, as it can warp or deform at temperatures above 50°C (122°F).

Handling: Store PLA products in a cool, dry place to prevent premature degradation. Avoid exposing them to direct sunlight or moisture for extended periods, as this can reduce their lifespan.

Microwave and Dishwasher Safety: PLA is generally not suitable for microwaving or dishwashing due to its sensitivity to heat. Use it for single-use purposes only.

Composting and Recycling Guidelines

Composting: PLA products are compostable, but they require industrial composting facilities to break down effectively. Check your local waste management services to see if they accept PLA for composting. Do not attempt to compost PLA at home, as backyard composting lacks the high temperatures needed for proper decomposition.

Recycling: PLA cannot be recycled with conventional plastics like PET or HDPE. Placing PLA in regular plastic recycling bins can contaminate the recycling process. Instead, dispose of it in compost bins designated for biodegradable materials or industrial composting programs.

Landfill Impact: If PLA ends up in a landfill, it will not decompose effectively due to the lack of proper conditions. Always prioritize composting whenever possible.

Conclusion

PLA (Polylactic Acid) is a revolutionary material that bridges the gap between convenience and environmental responsibility. Its plant-based origins, biodegradability, and eco-friendly nature make it a promising alternative to traditional plastics, particularly in food packaging. By adopting PLA, we can reduce our reliance on petroleum-based materials and address the growing issue of plastic pollution.

However, like any innovation, PLA is not without its challenges. Its sensitivity to high temperatures, reliance on industrial composting, and ethical concerns surrounding the use of food crops highlight the need for responsible use and proper infrastructure. PLA is best suited for cold or room-temperature food items and should be composted through the right channels to realize its environmental benefits fully.

For consumers and businesses alike, understanding how to use and dispose of PLA products is crucial. While PLA may not be a one-size-fits-all solution, it is a significant step toward a more sustainable future. As the world moves closer to a circular economy, materials like PLA play a vital role in reducing our environmental footprint.