In today’s world, plastic pollution has become one of the most pressing environmental challenges.

Each year, millions of tons of plastic waste end up in landfills and oceans, causing harm to wildlife and ecosystems.

Despite growing awareness, the demand for single-use plastic packaging continues to rise, making it difficult to find sustainable alternatives that can limit this alarming trend.

One such promising solution is moulded paper pulp trays. These trays are not only biodegradable but also made from recycled materials, offering an eco-friendly alternative to conventional plastic packaging.

They decompose naturally, reducing the burden on landfills and eliminating the risk of microplastics entering into our food chain.

The shift towards sustainable packaging has gained momentum as both businesses and consumers realize the importance of reducing plastic pollution.

Moulded paper pulp trays are emerging as a key player in this movement, combining functionality, affordability, and environmental responsibility.

By replacing plastic trays with these biodegradable options, we can take a significant step toward solving the plastic pollution crisis and creating a more sustainable future.

What is a Moulded Paper Pulp Trays?

Moulded paper pulp trays are eco-friendly packaging materials made from recycled paper or other natural fibers. These trays are designed to be sturdy, lightweight, and biodegradable, making them an excellent alternative to plastic trays.

Their production process involves shaping paper pulp into specific forms using molds or cavities.

Types of Moulded Paper Pulp Trays

Moulded paper pulp trays come in different types based on their manufacturing processes and applications:

1. Thermoformed Trays

These trays are created using heat and pressure, resulting in microbes free, smooth surfaces and precise shapes.

Commonly used for food packaging and premium products where appearance and safety are important.

2. Transfer Moulded Trays

These are formed in a mold and then transferred to another mold for drying.

Ideal for products requiring extra durability, such as industrial or electronic gadgets.

3. Processed Trays

Enhanced with bio-coatings (Shellac) or additional treatments to improve water or grease resistance.

Often used in food packaging, especially for takeaway meals and fresh produce.

How to Make Moulded Paper Pulp Trays?

The manufacturing of moulded paper pulp trays is an efficient and eco-friendly process that transforms recycled materials into versatile packaging solutions.

Let’s break down the key steps involved in their production:

1. Pulp Preparation

Recycled paper, cardboard, or natural fibers such as sugarcane bagasse, bamboo, rice husk, and wheat straw are broken down into a slurry by mixing them with water.

This mixture is blended until it forms a uniform and workable pulp.

In some cases, agricultural waste is also used to make the process more sustainable.

2. Moulding

The prepared pulp is then poured into molds cavities to give the trays their desired shapes.

Using vacuum suction, the pulp adheres to the mold’s surface, forming the initial structure of the tray.

This stage determines the shape, size, and thickness of the tray, allowing customization of trays.

3. Pressing and Drying

To enhance the strength and reduce moisture content, the moulded trays undergo pressing.

Heat and pressure are applied to solidify the structure and ensure a smooth finish. In certain cases, moist heat sterilization can be used for food applications.

The trays are then dried using ovens or natural air-drying methods to remove excess moisture.

4. Trimming and Finishing

After drying, the trays are trimmed to remove excess material or fur, which provides elegant appearance to trays.

Additional treatments, such as coatings for water or oil or grease resistance, can be done at this stage to get barrier properties in paper trays.

The finished trays are inspected for quality before being packaged for distribution.

Moulded Paper Pulp Trays vs. Plastic Trays

Moulded paper pulp trays stand out as an eco-friendly packaging solution, but how do they compare with plastic trays?

Here’s the comparison in a tabular format for better readability:

| Feature | Moulded Paper Pulp Trays | Plastic Trays |

| Eco-Friendliness | Biodegradable and compostable; made from recycled or natural fibers. | Non-biodegradable; takes hundreds of years to decompose. |

| Material Source | Recycled paper, agricultural waste, or natural fibers. | Petroleum-based. |

| Durability | Lightweight but less durable for long-term use. | Highly durable for long-term and multi-use applications. |

| Water & Grease Resistance | Requires coating for water/grease resistance. | Naturally resistant to water and grease. |

| Cost | Higher initial cost; cost-effective at scale. | Low cost due to mass production and global infrastructure. |

| Production Scalability | Moderate; advanced machinery required for large-scale production. | Highly scalable with established global infrastructure. |

| Recyclability | Easily recyclable and compostable. | Recyclable in limited cases; requires complex processes. |

| Environmental Impact | Low carbon footprint; reduces waste in landfills. | High environmental impact; major contributor to pollution. |

| Applications | Versatile: food packaging, electronics, pharma, healthcare, e-commerce. | Versatile: used in almost all industries. |

| End of Life | Decomposes naturally within months; can be composted. | Persists for centuries in landfills and oceans. |

In summary, moulded paper pulp trays excel in eco-friendliness, recyclability, and reducing carbon footprint but face challenges in cost, durability, and scalability.

While plastics dominate the market due to cost and durability, the environmental impact makes moulded pulp trays the preferred options for sustainable packaging.

However, the Asia-Pacific region is also witnessing rapid adoption, driven by industrialization, growing exports, and government initiatives promoting sustainability.

Benefits of Moulded Paper Pulp Trays

Moulded paper pulp trays are gaining popularity across industries due to their numerous advantages.

Let’s explore the key benefits in detail:

1. Environmental Benefits

Biodegradability and Compostability

Moulded paper pulp trays are made from natural fibers like recycled paper or agricultural waste, making them 100% biodegradable.

Unlike plastic, which takes hundreds of years to break down, these trays decompose naturally within a few months.

For example, a compostable food tray can return to the soil as organic matter, CO2 and water, enriching it instead of polluting the environment.

Reduction in Plastic Use

By replacing single-use plastic packaging with paper pulp trays, businesses can significantly reduce plastic waste.

For instance, a fast-food chain using biodegradable meal containers instead of Styrofoam boxes helps to prevent tons of non-recyclable waste from ending up in landfills.

Pharmaceutical industries rely heavily on PVC trays to support glass vial packaging, contributing significantly to plastic waste that harms the environment and human health. By replacing these PVC trays with seed-embedded paper pulp trays, we not only reduce plastic pollution but also create an opportunity to nurture life. These biodegradable trays decompose naturally, leaving behind seeds that grow into plants, supporting environmental regeneration. This transition helps safeguard human health by minimizing exposure to harmful plastics while fostering a greener planet, truly saving two lives: the life of people and the life of planet.

Use of Recycled Materials

These trays are often made from recycled paper or cardboard, reducing the need for virgin resources and lowering the overall carbon footprint.

For example, old newspapers and office paper can be transformed into protective packaging for delicate items like glass vial, ampoules, glassware or electronics.

2. Functional Benefits

Lightweight Yet Sturdy

Moulded paper pulp trays are lightweight, making them easy to handle and transport. Despite their lightness, they are strong enough to protect fragile items during shipping.

For example, egg cartons made of pulp can securely hold and provide cushion to eggs while being easy to carry.

Customizable Shapes and Sizes

The simple and easy manufacturing process allows for high customization, enabling the trays to be tailored as per customer requirements.

For example, a tech company can use custom-molded trays to package smartphones securely, by ensuring a snug fit and protection during transit.

Cost-Effectiveness at Scale

When produced in large quantities, moulded pulp trays are highly cost-effective.

For instance, farmers find them an economical choice for packaging fruits, reducing costs while meeting eco-friendly standards.

3. Consumer Appeal

Growing Demand for Sustainable Products

Today’s consumers are more environmentally conscious and prefer brands that prioritize sustainability.

By using moulded pulp trays, businesses can enhance their brand image and attract eco-conscious customers.

For example, a cosmetics company that packages its products in biodegradable pulp trays instead of plastic can appeal to consumers seeking green alternatives.

Challenges in Adoption of Moulded Paper Pulp Trays

While moulded paper pulp trays offer numerous benefits, their widespread adoption faces certain challenges.

Understanding these obstacles can help businesses and manufacturers to navigate and address them effectively.

1. Manufacturing Limitations

Production Capacity

Scaling up production to meet growing demand can be challenging, especially for industries requiring large volumes of packaging like Apple and Dell.

Current production facilities may struggle to produce moulded paper pulp trays at the same speed as plastic packaging, leading to supply chain issues.

Quality Consistency

Ensuring uniformity in thickness, strength, and shape can be difficult, particularly when using recycled materials.

Variations in pulp quality or the manufacturing process may lead to defects.

Example: A pharma company may face delays if suppliers cannot meet the demand for consistent-quality trays.

2. Initial Costs Compared to Conventional Packaging

The upfront cost of adopting moulded paper pulp trays is often higher than that of conventional plastic because of infrastructure and other reasons. This includes:

Raw Material Costs: While recycled materials are cheaper, the processes and technology to convert them into trays can be costlier.

Machinery Investment: Manufacturers need specialized equipment and a trained work force, which requires significant initial investment.

Perceived Expense: Businesses, especially small enterprises, may find difficult for the transition from plastic to paper.

Example: A small bakery shop considering a switch to compostable trays may hesitate due to the higher purchase price compared to plastic containers.

Despite these challenges, the adoption of moulded paper pulp trays is steadily increasing, driven by the global push for sustainability.

Innovations in Moulded Pulp Technology

Moulded pulp technology has seen remarkable advancements, enhancing its functionality, scalability, and environmental impact.

These innovations are shaping the future of sustainable packaging and expanding its applications across industries.

1. Advancements in Machinery for Precision and Scalability

Modern machinery has transformed the production of moulded paper pulp trays, enabling greater precision, efficiency, and versatility.

This is particularly relevant for industries like pharmaceuticals, where sustainable alternatives to traditional PVC blister packaging are gaining traction.

Automation

Automated systems ensure faster production and consistent quality, meeting the stringent demands of the pharmaceutical sector.

For example, dry-mold fiber technology is being used to create precise moulded pulp blister packs for tablets and capsules.

These systems allow for uniform cavities to securely hold medications, providing the same level of protection as PVC films while being biodegradable.

Scalability

Advanced machinery supports large-scale production without compromising on quality.

In pharmaceutical applications, this scalability is critical as it allows manufacturers to meet high-volume demands for blister packaging.

For instance, a pharmaceutical company producing millions of tablets can transition from PVC blister packs to moulded pulp alternatives, scaling production efficiently to ensure supply chain stability.

Custom Designs

Improved molding techniques now enable intricate designs tailored to specific product needs.

In the case of pharmaceuticals, pulp molding technology can create customized cavities that securely fit tablets or capsules, protecting them from breakage and ensuring proper alignment within the packaging.

This makes moulded pulp a viable alternative for replacing traditional PVC blister packs.

Example: As seen in the adoption of dry-mold fiber technology for tablet blister packaging, moulded pulp trays can be designed with precise cavities to hold medications securely. These trays eliminate the need for PVC films, significantly reducing plastic waste while maintaining the functionality required for pharmaceutical packaging.

2. Use of Advanced Materials Like Agricultural By-Products

Incorporating agricultural waste into pulp production has enhanced sustainability. Materials like sugarcane bagasse, wheat straw, and rice husks are now commonly used.

Eco-Friendliness

These materials reduce reliance on virgin paper, promoting waste-to-resource initiatives.

Cost-Effectiveness

Using agricultural by-products lowers raw material costs while reducing environmental waste.

Example: A fruit exporter might use trays made from sugarcane bagasse to hold and protect fresh produce.

3. Integration of Coatings for Water and Grease Resistance

To broaden their usability, moulded pulp trays can now be coated with biodegradable films that repel water and grease.

Food Packaging

Coated trays are ideal for holding oily or wet food items without compromising the integrity of the packaging.

Sustainability

These coatings are plant-based and compostable, ensuring the trays remain eco-friendly.

Example: Takeaway containers with grease-resistant coatings are becoming popular in fast-food chains.

The company shipping vaccines or biologics in glass vials can use these trays to maintain the required cold chain conditions while minimizing environmental impact, offering both functionality and sustainability.

4. Digital Tools for Design and Prototyping

Digital technologies are revolutionizing the design process:

3D Modeling and Prototyping

Designers can create and test tray designs digitally, reducing errors and production costs.

Customization

Businesses can experiment with designs tailored to specific products or branding needs.

Example: A company can test various designs for protective packaging using 3D prototypes before mass production.

5. Seed-Embedded Paper Pulp Trays

An exciting innovation is the creation of seed-embedded moulded pulp trays that promote plant growth.

Concept

These trays contain seeds of flower or medicinal plants. After use, the trays can be planted in soil, where they decompose and allow the seeds to sprout.

Application

Ideal for eco-conscious brands or gifting, combining functionality with sustainability.

Impact

They encourage environmental responsibility while adding value to packaging.

Example: A skincare brand can package its products in seed-embedded trays containing medicinal plant seeds, reinforcing its commitment to nature.

Innovations in moulded pulp technology are expanding its versatility, sustainability, and appeal.

From advanced machinery and materials to water-resistant coatings and seed-embedded trays, these developments are paving the way for a greener future while meeting diverse industrial needs.

6. Agricultural Innovations - Seedling Trays

Traditional plastic seedling trays, commonly used for germinating plants, contribute to significant plastic waste. Moulded pulp seedling trays offer a biodegradable and compostable solution. These trays:

Support Plant Growth

Provide a sturdy yet breathable environment for seedlings, promoting healthy root development.

Eliminate Plastic Waste

Decompose naturally in the soil after planting, reducing the reliance on single-use plastic trays.

Enhance Convenience

Farmers can plant seedlings directly with the trays, eliminating the need to remove and dispose of plastic containers.

Example: A nursery growing saplings for large-scale plantations can replace plastic trays with moulded pulp alternatives, reducing waste while maintaining efficiency.

Industries Using Moulded Paper Pulp Trays

Moulded paper pulp trays are versatile and cater to a variety of industries, thanks to their eco-friendly nature and functional benefits.

Here’s how they are making an impact across different sectors:

1. Food and Beverage Industry

Moulded pulp trays are widely used in food packaging because they are safe, durable, and environmentally friendly. Examples include:

Egg Cartons: One of the most common uses, these trays protect eggs during storage and transport while being biodegradable, lightweight and stackable.

Fruit Trays: Ideal for holding fruits like apples, oranges, and pears, keeping them secure and preventing bruising during transit.

Meal Containers: Compostable trays for takeaway meals, perfect for restaurants and food delivery services aiming to reduce plastic waste.

Example: A farm supplying eggs to supermarkets can use pulp trays instead of plastic trays, enhancing its sustainability credentials.

2. Electronics Industry

In the electronics industry, moulded pulp trays provide excellent protection for delicate devices. They absorb shocks and prevent damage during shipping and handling.

Protective Packaging: Used for items like smartphones, laptops, and computer components, these trays are custom-molded to ensure a snug fit and cushioning.

Example: A mobile phone manufacturer can use pulp trays for packaging, reducing plastic usage and appealing to environmentally conscious buyers.

3. Medical and Healthcare Industry

The healthcare sector benefits from the hygiene and biodegradability of moulded pulp trays, especially for disposable applications.

Biodegradable Trays: Used for packaging medical instruments, syringes, or test kits, these trays are safe for one-time use and can be composted after disposal.

Example: A hospital using pulp trays for medical disposables minimizes its reliance on single-use plastics, contributing to waste reduction efforts.

4. Industrial and E-Commerce Sector

For industries dealing with fragile products, moulded paper pulp trays offer reliable cushioning and protection.

Cushioning for Fragile Products: Perfect for shipping glassware, ceramics, and other breakable items.

E-Commerce Packaging: As online shopping grows, businesses increasingly use these trays for sustainable packaging.

Example: An e-commerce retailer shipping delicate items like vases or kitchenware can use moulded paper pulp trays to prevent breakage while maintaining eco-friendly practices.

Market Trends for Moulded Pulp Trays

The increasing emphasis on sustainability and environmental responsibility has created favorable market conditions for moulded pulp trays.

These trends highlight the growing demand and support for eco-friendly packaging solutions.

Global Market Growth Projections for Moulded Pulp Trays

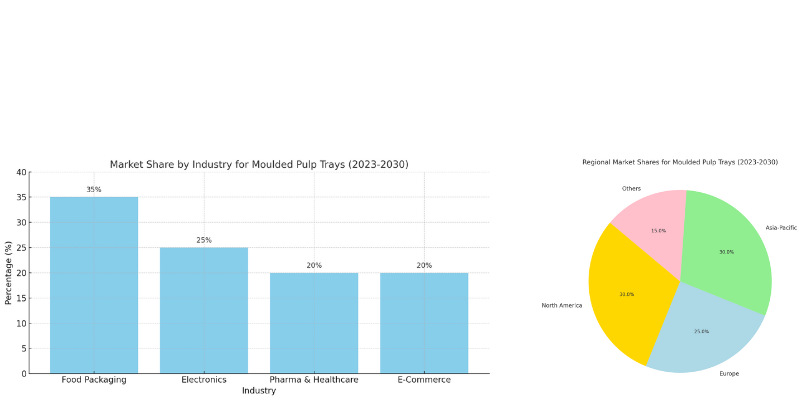

The global moulded pulp tray market is experiencing significant growth. It is projected to expand at a compound annual growth rate (CAGR) of 4-6% from 2023 to 2030.

This growth is driven by increasing demand across industries such as food packaging, electronics, pharma, and healthcare.

Key factors contributing to this market expansion include stringent environmental regulations, the rise of online shopping requiring sustainable shipping solutions, and the need for protective yet eco-friendly packaging in industries dealing with fragile goods.

Regionally, North America and Europe are leading the market due to strong regulations and consumer awareness.

Conclusion

Moulded paper pulp trays represent a powerful forward step in sustainable packaging. As the world stuck with the challenges of plastic pollution and environmental degradation, these trays offer an eco-friendly, practical, and versatile solution that meets the demands of modern industries and eco-friendly conscious consumers.

From food and beverage to electronics, pharma, healthcare, and e-commerce, their applications are diverse, proving that sustainability and functionality can coexist.

While challenges like initial costs, durability and functionalities, the benefits of moulded pulp trays—biodegradability, recyclability, and alignment with global sustainability goals—far outweigh their limitations.

With advancements in technology, growing consumer demand for green products, and supportive regulatory frameworks, the future of moulded pulp trays is bright.

By embracing this innovative packaging solution, businesses can not only reduce their environmental footprint but also position themselves as leaders in the movement toward a circular economy.

Together, we can pave the way for a more sustainable and eco-conscious world, one moulded tray at a time.