Jute packaging plays a significant role in modern packaging due to its eco-friendly, sustainable, renewable, compostable and versatile nature.

The role of packaging is vital in safeguarding and maintaining the integrity of products, yet it also gives rise many environmental issues.

By focusing on biodegradable and renewable materials, packaging industry has taken significant strides towards sustainability.

In this pursuit, jute packaging, which is also known as a natural fiber packaging has emerged as a pioneer and offer a best option for green packaging all over the globe.

Jute is primarily cultivated in tropical and subtropical countries like India, Bangladesh, China and Thailand.

The Botanical Origin of Jute

Jute is a natural fiber derived from plants. It belongs to the genus Corchorus, primarily Corchorus olitorius and Corchorus capsularis.

These plants comes under the Tiliaceae family and well known for their fibrous stems.

The extraction and processing of jute or golden fiber involve several stages from cultivation to the production of usable fibers.

Jute plants, primarily Corchorus olitorius and Corchorus capsularis are cultivated in tropical and subtropical countries with warm temperatures and high humidity.

Favorable condition for cultivation

Temperatures: More than 25 °C and Relative Humidity: 70–90 %RH

The cultivation process involves sowing jute seeds in well-prepared soil during the appropriate growing season (growing season in India is March to May).

Jute plants have a relatively short growing cycle, typically around 4-6 months.

The plants grow tall and straight up to 10 – 12 feet (3 – 3.5 meters).

Harvesting is done when the plants are in full bloom but before seed maturity. This ensures that the fibers are at their strongest.

Retting is a crucial step in jute processing for separating the fibers from the non-fibrous parts of the stem.

1. Stem or Ribbon Retting and

In stem retting, harvested jute plants are bundled and immersed in water or spread in the field for natural exposure of sunlight, dew and rain.

In water retting, harvested jute submerged in ponds or rivers to encourage microbial activity. This breaks down the non-fibrous components.

After retting, the jute stems are ready for fiber extraction. The softened fibers can be stripped off from the stems using a mechanical process or by hand.

The fibers are typically concentrated in the outer bark or bast of the stem.

The extracted jute fibers are washed to remove any remaining impurities, residues or retting agents.

After washing, the fibers are dried either through sun drying or mechanical drying methods.

Once dried, the jute fibers are formed into bales for ease of handling, transportation, and storage.

The baling process involves compressing the fibers into dense, manageable units.

Bales of jute fibers are then packaged and prepared for distribution to manufacturers.

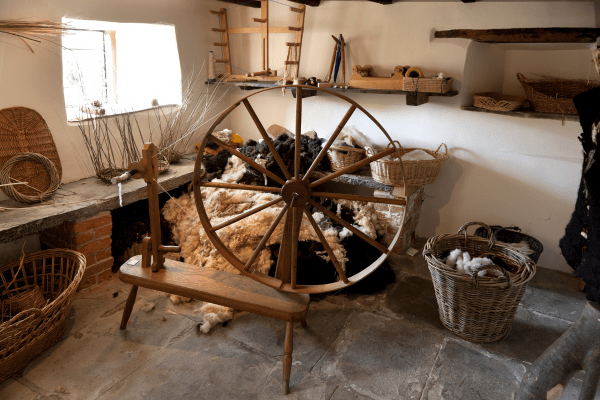

Jute fibers can be spun into yarn using traditional spinning methods or modern spinning machinery.

Spinning transforms the loose jute fibers into a continuous thread, which can be further processed into various products.

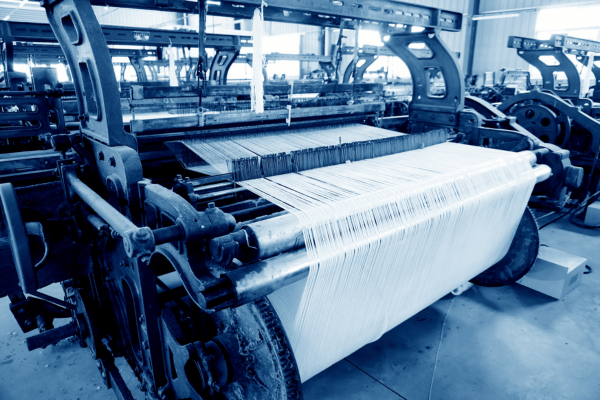

Jute yarn can be woven into fabrics using traditional hand looms or modern weaving machines.

The resulting jute fabric can be used for a wide range of applications, including sacks, bags, carpets, clothing, and packaging materials.

If desired, jute fabrics can undergo dyeing processes to add color or patterns.

Throughout this sustainable agriculture practice, from cultivation to the manufacturing of dyeing and finishing, sustainable practices can be incorporated to enhance the eco-friendly nature of jute as a material.

Jute is considered as a best biodegradable material due to its natural composition and the ability of its fibers to break down over time through the microorganisms.

Several factors are contributing for biodegradation of jute.

Jute fibers are derived from the inner bark (bast) of the Corchorus plants, primarily Corchorus olitorius and Corchorus capsularis.

Being a plant-based fiber, jute is composed of cellulose, hemicellulose and lignin, which are organic compounds commonly found in plant cell walls.

Cellulose is a complex carbohydrate and the main structural component of plant cell walls.

Jute fibers have a high cellulose content, making them more susceptible towards enzymatic breakdown by microorganisms.

When jute products, such as sacks, bags or textiles, are exposed to the environment, microorganisms initiate the process of decomposition by secreting enzymes that break down the cellulose and other organic components of jute.

Biodegradation is influenced by environmental conditions, including temperature, moisture and oxygen availability.

This natural fiber biodegrades more efficiently in warm and humid conditions where microbial activity is higher.

Jute biodegrades through aerobic (oxygen-dependent) decomposition.

Microorganisms utilize oxygen to break down the complex organic molecules of jute into simpler compounds like carbon dioxide, water and biomass.

The biodegradation process of jute can vary depending on the thickness and structure of the material as well as the environmental conditions.

In general, jute products left in natural settings can break down within a few months to a few years, returning to the soil as organic matter.

Jute can be incorporated into composting systems, where it decomposes to produce nutrient-rich compost.

The biodegradability of jute contributes to its low environmental impact compared to non-biodegradable materials like plastics. Jute products do not persist in the environment as long-term pollutants.

Comparing the carbon footprint of jute packaging with plastic materials, involves various factors across the entire life cycle of each material.

Jute proves the best alternative option for conventional plastic packaging by considering its biodegradability, renewability, strength and versatility.

One of the primary environmental benefits of jute is their biodegradability. Jute fibers are natural and decompose over time followed by improving soil health.

The production of jute fibers has a lower carbon footprint compared to the manufacturing of synthetic materials like polyester or polypropylene.

Jute is a renewable resource as it is derived from the jute plant, which is cultivated annually.

Jute play a crucial role in preventing soil erosion by stabilizing soil on slopes, embankments and construction sites.

Jute protect soil from erosion during the early stages of vegetation establishment.

Jute provide a natural cover that promotes the growth of vegetation, contributing to the restoration of ecosystems.

Jute geotextiles act as a permeable barrier that allows water to pass through it while on other hand, trapping sediment and impurities.

This enhances water filtration, preventing the transport of soil particles into water bodies and maintaining water quality.

The production of jute geotextiles involves fewer synthetic chemicals and energy compared to the production of some synthetic material.

Jute is in line with the principles of a circular economy, where materials are designed to be recycled, reused or naturally decomposed.

Carbon neutrality of jute means balancing the carbon emissions generated throughout the entire lifecycle of jute production, from cultivation to processing and disposal, with an equivalent amount of carbon removal.

When added to compost piles, jute materials contribute to the creation of nutrient-rich compost that can be used to improve soil structure and support plant growth.

Jute possesses notable strength and adaptability, making it a preferred choice for various packaging applications.

Jute fibers are inherently strong and resilient, making them suitable for packaging heavy or bulky items.

The natural tensile strength of jute contributes to the durability of packaging materials, ensuring they can withstand the stresses of handling and transportation.

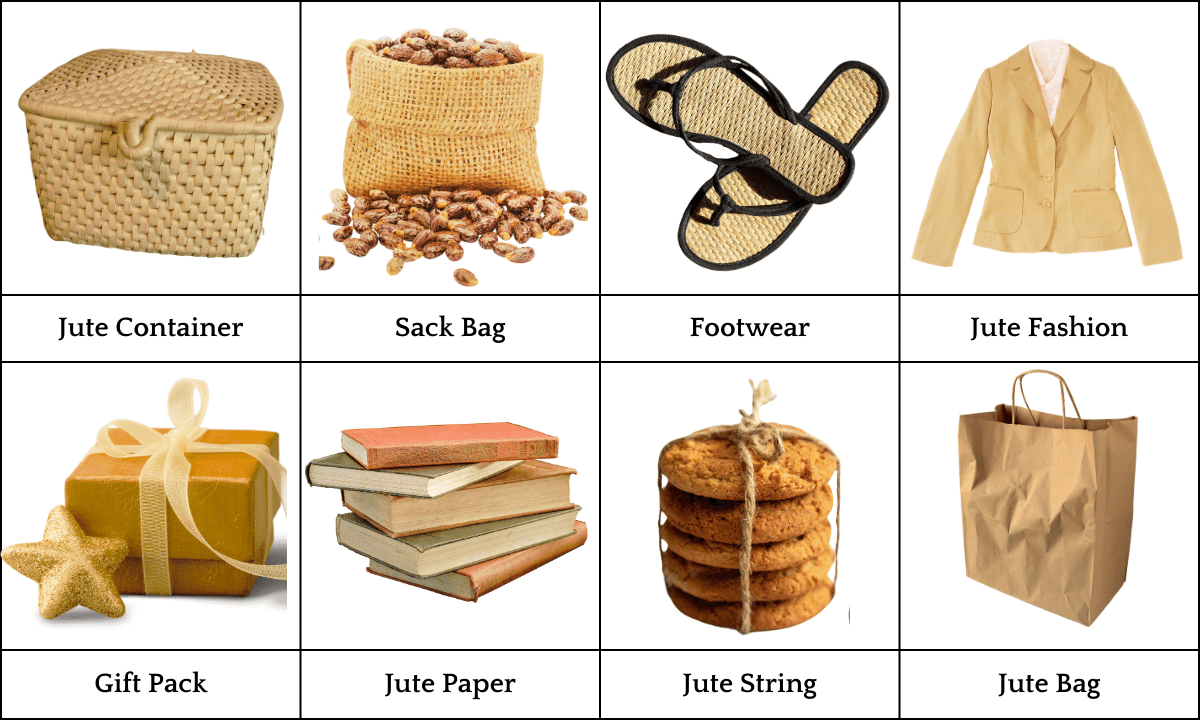

Jute is a versatile material that can be easily woven, allowing for the creation of a wide range of packaging products such as sacks, bags, and wraps.

Jute possesses natural shock-absorbing properties, providing a cushioning effect that helps to protect fragile and delicate items from impact and vibration during transit.

Jute is a breathable material, allowing air circulation through the packaging.

This feature is beneficial for certain products like agricultural products that require ventilation to maintain freshness.

The breathability of jute helps to regulate temperature and moisture levels, preventing the buildup of humidity that can lead to mold or mildew.

Jute is often more cost-effective than alternative packaging materials.

Its natural strength, shock-absorbing properties, breathability, sustainability and cost-effectiveness contribute to the popularity of jute in the modern packaging industry.

Jute packaging is not limited to a specific sector; its versatility makes it suitable for a wide range of industries.

Jute known for its strength and breathability, making it an ideal material for agricultural packaging.

The breathable nature of jute allows for proper ventilation, promoting healthy plant growth.

Traditional jute sacks and bags have been widely used for packaging and transporting various agricultural products, including grains, potatoes, and coffee.

There are several types of jute bags available for agricultural product packaging:

1. Standard Jute Bags: These are the most common type of jute bags used for packaging agricultural products. Standard jute bags come in various sizes and weights, making them suitable for packaging a wide range of agricultural products, from grains to fruits and vegetables.

They offer best protection against external elements but may not be ideal for products prone to moisture sensitive unless additional precautions are taken.

2. Laminated Jute Bags: These bags are coated with a thin layer of lamination, typically made of polyethylene or similar materials, which makes them more resistant to moisture and provides better protection for the packaged products.

The lamination provides an extra barrier against moisture, making these bags more suitable for products like coffee beans, cocoa, or spices that are sensitive to moisture.

They also offer better resistance to tearing and puncturing, enhancing the durability of the packaging.

3. Jute Sacks: Sacks are typically larger in size and used for bulk packaging of grains, seeds, and other agricultural products.

They often feature reinforced stitching and thicker jute fibers to withstand the weight and pressure of bulk products.

Jute sacks are commonly used in warehouses, mills, and transportation for storing and moving large quantities of agricultural goods.

4. Jute Mesh Bags: These bags have a mesh-like structure, allowing for better air circulation, which is useful for products like onions, potatoes, and other vegetables.

The mesh design also allows consumers to see the contents of the bag easily, which can be advantageous for marketing purposes.

5. Jute Wine Bags: Specifically designed for packaging wine bottles, these bags offer both protection and an eco-friendly alternative to traditional packaging materials.

They are typically padded or lined to cushion the bottles and prevent breakage during transportation.

Jute wine bags are an eco-friendly alternative to traditional wine packaging materials like cardboard or plastic, making them popular among environmentally conscious consumers.

Jute’s rough texture makes it suitable for manufacturing of mats and flooring materials.

Elevate your home with the natural beauty and sustainability of jute carpets.

Crafted from 100% eco-friendly jute fibers, these carpets add a touch of rustic elegance while promoting a greener planet.

Their durable, woven texture not only enhances the visual appeal of any room but also stands up to everyday wear and tear.

Perfect for living rooms, offices, or any space in need of a stylish upgrade, jute carpets offer a unique blend of comfort and sustainability.

Choose jute for a stylish, eco-conscious solution that complements any decor. Explore this collection and make a sustainable choice today!

Jute fibers have been employed in the paper industry, contributing to the production of jute paper.

The diverse applications of jute bags showcase their adaptability and sustainability across different industries, emphasizing their role in promoting sustainable practices.

While jute packaging offers various advantages, there are also common challenges associated with its use, including cost considerations, availability and durability.

While jute is often cost-effective compared to some premium packaging materials, its price can vary based on factors such as quality, processing, and customization.

Jute cultivation is primarily concentrated in certain regions like India, Bangladesh and Thailand and seasonal variations can affect availability.

While jute is naturally durable, it may not match the durability of certain synthetic materials like plastics.

Jute has a level of moisture sensitivity that can impact its performance in certain conditions.

Several ongoing initiatives are implemented to overcome challenges associated with jute packaging.

Ongoing R&D initiatives focus on improving the strength, durability and moisture resistance of jute fibers.

Researchers are exploring innovative processing techniques and treatments to enhance the performance of jute, making it more competitive with synthetic materials.

Initiatives involve blending jute with other materials (such as recycled plastics or other plant-based fibers) to create hybrid materials that offer improved properties.

The combination of jute with other materials aims to address specific challenges, such as moisture sensitivity, while maintaining the eco-friendly characteristics of jute.

Organizations are working to establish standards and certifications for jute packaging to ensure quality and performance.

These standards provide guidelines for manufacturers and promote consistency in the production of jute packaging.

Initiatives are in place to enhance the skills and knowledge of jute farmers, manufacturers and workers involved in the jute industry.

Capacity-building programs aim to improve cultivation practices, processing techniques and overall efficiency in the jute supply chain.

By combining these ongoing initiatives, stakeholders aim to address the challenges associated with jute packaging, making it a more attractive and competitive option in the sustainable packaging.

In conclusion, Jute Packaging emerges not only as a sustainable alternative but as a symbol of responsible and environmentally conscious choices in the world of packaging.

The golden fiber, with its natural elegance and versatility, provides a unique solution that transcends the boundaries of conventional packaging materials.

By selecting Jute Packaging, we contribute a greener tomorrow, reducing our ecological footprint and fostering a healthier planet.