In this rapidly growing world of technology, 3D printing is emerging as a groundbreaking innovation for the packaging industry. Because, packaging is often considered as the major contributor to plastic pollution or environmental damage.

Thanks to 3D printing.

This new technology is not only reducing the negative environmental impact but also offering endless creativity, functionality and efficiency in packaging design and production.

In this post, we will explore how 3D printing is reshaping the packaging industry by keeping sustainability in mind.

Introduction

What is 3D Printing in Packaging?

3D printing involves the creation of real objects or packaging materials from a computerized or digital file. In simple terms, material will be created by topping melted material layerwise.

3D printing is also known as additive manufacturing in certain industries.

Unlike traditional plastic moulding methods, where generation of material waste is very common, 3D printing eliminates that waste and thus increasing the production efficiency.

This technology was invented long back, but now it is gaining traction in packaging by considering today’s need for sustainable alternatives.

Additionally, 3D printing can be feasible with a varieties of materials, including plastics, glass, paper, wood, carbon and even food-grade materials.

Types of 3D Printing Technology

There are different types of 3D printing methods to create packaging materials and each one has its own benefits.

Here are a few most common methods.

1. Fused Deposition Modeling (FDM)

FDM is the most commonly used method, where a thermoplastic filament is melted and extruded into desired objects or packaging materials (layer by layer).

This method is very popular in the development process, where it reduces development time from weeks to a few hours for making a prototype for design approval.

2. Selective Laser Sintering (SLS)

A laser beam is used to convert powder resin into solid objects. This method is ideal for designing complex shapes.

It is used to produce durable packaging components for machinery, where strength, accuracy and precision are extremely crucial.

Plus, the ability to work with a wide range of materials, including plastics, metals and ceramics, makes SLS very popular.

3. Stereolithography (SLA)

In this method, a UV laser is used to create a packaging component from liquid resin.

It is suitable for both prototype testing and small-scale manufacturing of complex packaging components.

4. Selective Laser Melting (SLM)

This method is similar to selective laser sintering (SLS), but here metal powder is used to create strong and durable components.

Generally, it is used to produce strong, functional and customized components for industrial applications.

However, this method is costly to produce articles.

The Environmental Impact of Traditional Moulding Methods

Packaging has been playing an important role in protecting products, but the way we are using it today has significant environmental consequences.

Here are some of the issues with traditional packaging methods.

1. Waste Generation

With the traditional moulding methods, we are generating huge amounts of material waste during the manufacturing of packaging materials, which ends up in landfills or oceans if not recycled, contributing to the growing crisis of plastic pollution.

Moreover, the non-biodegradable nature of plastics is making this problem even worse, as they persist in the environment for a longer time (100-500 years).

2. Resource Depletion

Usage of traditional materials and methods requires the use of natural resources like crude oil, leading to the depletion of limited fossil fuels.

3. Carbon Footprint

Manufacturing of packaging materials, transporting them from one place to another places and, of course disposing of them after their usage creates massive emission of greenhouse gases.

With these problems, the need for a sustainable alternative is very crucial today.

How does 3D Printing Contribute to Sustainable Packaging?

3D printing technology provides numerous benefits in packaging, especially when it comes to sustainability, customization and cost-effectiveness.

Some of the key advantages are here.

1. Quick Prototype Testing

In traditional moulding methods, a prototype takes time from few weeks to a month for making a pilot mould and articles. But in 3D printing this time can be reduced significantly and an article can be created within a day without the additional cost of a mould.

This accelerates the design process, reduces the time to market and minimize the risk of errors before commercialization.

2. Customization

Using 3D printing, packaging can be easily tailormade for every different product, reducing the need for fillers or extra packaging materials for cushioning purposes.

Customized packaging always provides better product protection and increases brand value.

It also opens up new opportunities for innovative designs that can stand out in a crowded market.

3. Possibility for Complex or Intricate Design

3D printing technology allows to create intricate or complex designs easily that would be difficult with traditional mould making process.

4. Sustainability

As the world faces the environmental challenges of traditional packaging methods and materials, 3D printing offers a more sustainable alternative.

By using recyclable and biodegradable materials, we can reduce material waste and support a circular economy system.

Additionally, the ability to print on demand eliminates overproduction and storage of packaging materials at plants.

This helps to reduce overproduction and minimizes the storage of unused packaging materials in companies’ warehouses.

5. Functional Packaging

Nowadays packaging is not only a protective layer. We can integrate smart or active packaging features, like biosensors, RFID tags, NFC tags or even nanotechnology directly into packaging material at the time of production, making this technology effective and efficient.

6. No Mould Cost

Making packaging components with the traditional method requires mould costs and a lead time of a few weeks to months for just making the mould.

But with 3D printing technology, we don’t need a mould to create an object since it is made from a digital file within a few hours, making the development process much quicker and cheaper.

7. Post-Printing Features

Post-printing features, like embossing and debossing can be possible with 3D printing at the time of manufacturing, further reducing the process time and additional steps. While in the traditional moulding process, these features can’t be possible.

8. Heat-Sensitive Materials

Certain heat-sensitive materials, like bio-plastics are difficult to process with traditional moulding methods, while in the case of 3D printing technology, these bio-plastics can be used without degrading material qualities.

Practical Applications of 3D Printing in Packaging

Many companies are using 3d printing technology in their development process or short-run manufacturing.

1. PepsiCo and Marvel Studios for Movie Promotion

PepsiCo and Marvel Studios collaborated with each other to promote the “Black Panther” movie by using 3D printed packs.

In their promotional kit, aluminium cans, a Samsung tablet, comic books and a 3D-printed Black Panther mask are included, where the Black 3D Printed Mask was the centre of attraction in the promotional kit.

This promotional strategy got huge responses from social media, which showcasing that how 3D printing can create customized design quickly and affordably.

This collaboration highlights how 3D printing can be used to promote product packaging at lower cost and in less time.

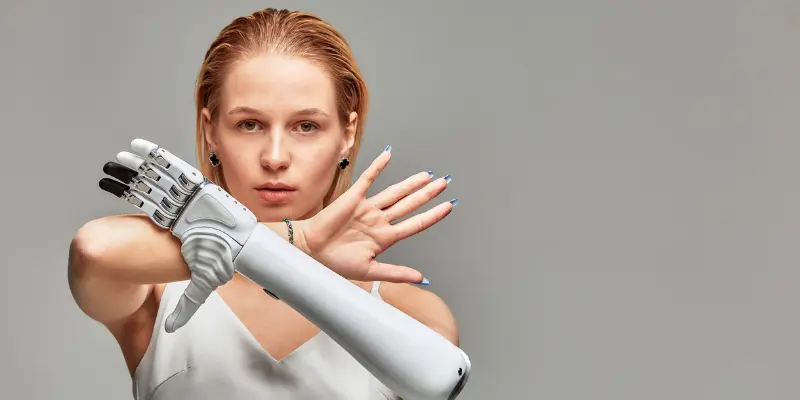

2. 3D Printed Prosthetics or Arms

Using 3d printing, we can create prosthetics (artificial body parts) and orthotics (supportive devices).

Companies like E-Nable are using 3D printing to create custom prosthetic limbs that are cheaper and tailored as per patients’ needs.

This technology helps to create artificial body parts with accuracy and precision which ensures comfort and functionality for the human.

For example, a 3D printed prosthetic arm can be designed to match the particular patient’s size, shape and preferences, making it more comfortable than traditional options.

This innovation makes prosthetics more accessible, customizable and cost-effective, improving the quality of life for many patients.

Challenges and Limitations of 3D Printing in Packaging

While 3D printing offers numerous benefits, it also comes with a few challenges.

1. High Setup Costs

The initial investment in 3D printing setup for mass production is quite costly as compared to traditional manufacturing setup, which makes it difficult for small-scale business units.

However, over time the cost of this technology goes down.

2. Adoption and Scalability

Adopting 3D printing for packaging on a global scale is still under progress.

To meet demand and supply for larger companies is difficult and challenging because of newer technology and fewer infrastructure.

3. Material Selection

Though the material selection for 3D printing is growing, traditional packaging materials like plastics and cardboard remain more cost-effective and widely available.

While some other biodegradable materials are available, but they are costly and less durable than traditional packaging materials.

The cost of specialized 3D printing materials can be a barrier for its widespread adoption, especially for small scale-business owners.

The Future of 3D Printing in Sustainable Packaging

Despite having the above challenges, the future of 3D printing in packaging looks promising and attractive.

1. Technology Upgradation

3d printing technology is growing rapidly and soon we will have new materials and methods for producing more sustainable packs.

For example, bioplastic filaments and multi-material printing or co-axial printing can be possible in the near future, providing more options for sustainable packaging.

2. Growing Trend For 3D Printing

Lots of companies are taking interest in 3d printing by considering its affordable cost and quicker turnaround time in development and manufacturing.

From e-commerce packaging to food packaging, the use of 3D printed packaging is expected to expand rapidly.

With the right technological advancement and support, 3D printing could become more common in packaging and manufacturing.

3. Consumer Demand

The new generation are becoming more aware about the negative environmental impact of traditional packaging, so they are supporting products and packaging which are aligned with the sustainability.

This demand will push companies to explore and adopt 3D printing as part of their sustainability strategy.

Conclusion

Use of 3D printing in packaging allows to create sustainable, customizable and functional packaging materials. It has the ability to create intricate designs, reduce material waste and the potential to incorporate smart technology into packaging material directly.

More businesses are discovering exciting opportunities to innovate and bring more sustainable packaging solutions to life.

With support from industry leaders like Stratasys, Materialise and EOS GmbH, 3D printing in packaging is steadily becoming a reality. And as we look ahead, the future of packaging is looking brighter and greener than ever before.