Mycelium packaging material also known as mushroom packaging material, has gained widespread popularity and is poised to emerge as a leading sustainable and renewable material in the future.

In an era where environmental concerns are at the top of global discussions, the need for sustainable material to replace non-biodegradable material has become imperative.

It is estimated that 1.5–4% of global plastics production ends up in the oceans every year because of various reason such as littering, excessive use of single use plastics, poor waste management infrastructure, packaging and industrial revolution, fishing and aqua cultural activity.

These all plastics break down into microplastics, which are accessible to both marine and terrestrial animals. These microplastics then enter into the food chain and ultimately reach to humans by consuming seafood or animal meat, which have serious health concerns.

Table of Contents

Introduction

Mycelium packaging material is a sustainable alternative to traditional non-biodegradable packaging material, which can utilize the root structure of fungi to create biodegradable and environmentally friendly packaging material.

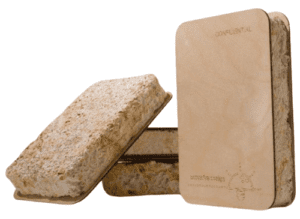

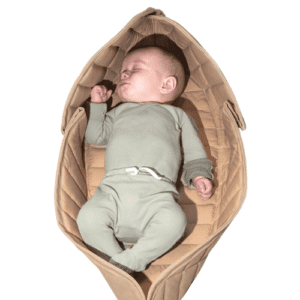

Mycelium packaging material or fungal packaging material can be transformed into a variety of products, ranging from stylish handbags to innovative packaging solutions and even construction materials, such as bricks called bio-bricks.

From reducing plastic pollution to promoting sustainable resource, mycelium stands as a symbol of environmentally conscious innovation in the packaging industry.

What is mycelium packaging material?

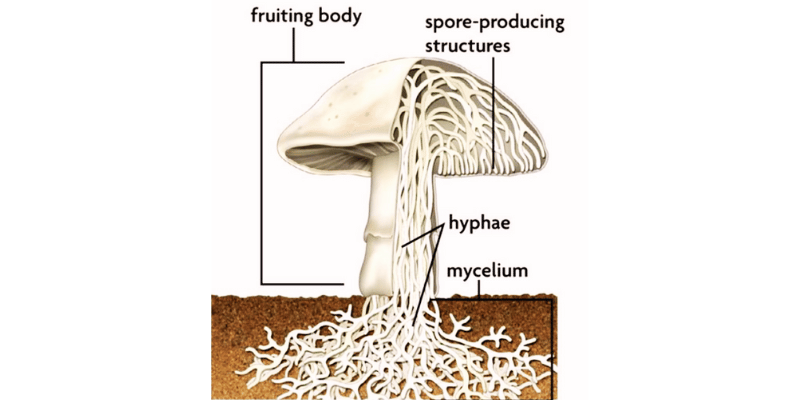

Mycelium is the thread-like vegetative part of a fungus that plays a fundamental role in the growth and development of mushroom fungi. Their primary role is to absorb and distribute nutrition for the fungi.

This natural material is known for its ability to form a dense network of fibers, which is creating a strong, durable and versatile structure.

Mycelium produces enzymes that break down organic matter and secretes a natural adhesive or “biological glue” to bind organic waste materials together for forming a cohesive and strong matrix.

Mycelium primarily consists of natural polymers like chitin, cellulose and proteins, which are making them ideal choice for food, nutraceuticals, pharmaceuticals, pesticides, alternative protein sources and notably, as a substitute for plastics packaging material, such as Styrofoam.

“Armillaria ostoyae” commonly known as the honey fungus is the largest know fungi organism. It covers an estimated area of over 3.4 square miles (8.8 square kilometers) in the Malheur National Forest in Oregon, USA.

What is the difference between mycelium and mushroom?

| Mycelium | Mushroom |

| Mycelium is the thread-like vegetative part of a fungus, consisting of a network of filamentous structures known as hyphae. | Mushroom is the reproductive structure, emerging from the mycelium under specific environmental conditions. |

| Mycelium is typically found underground or within soil. | Mushroom often visible above the ground. |

| Absorption and distribution of nutrients for fungus is their primary role. | Mushrooms produce and disperse spores, which can germinate and form new mycelium. |

| Mycelium is the precursor to mushroom and can persist for much longer periods. | Mushroom is relatively short-lived structures. |

Which mycelium species are most widely used?

Currently, scientists have identified a lot of different types of fungi, but still there are so many types to be discovered. This means there is a lot of exciting potential for finding new fungal species in the future.

1. Pleurotus ostreatus (Oyster Mushroom)

Oyster mushrooms are commonly utilized in mycelium packaging material due to their fast growth and ability to degrade a variety of substrates.

2. Ganoderma lucidum (Reishi Mushroom)

Reishi mushrooms possess strong mycelium that can be used in packaging materials. Additionally, they offer potential health benefits and are used in traditional medicine.

3. Trametes versicolor (Turkey Tail Mushroom)

Turkey tail mushrooms are known for their efficient decomposition of organic matter, making them also a special for mycelium packaging material.

4. Phanerochaete chrysosporium

This white rot fungus is well-known for its ability to degrade lignin, a key component in various waste materials. Its robust mycelium makes it suitable for mycelium packaging material.

5. Schizophyllum commune (Split Gill Mushroom)

Split gill mushrooms are notable for their adaptability towards different substrates and rapid growth, making them a practical choice for mycelium packaging material.

In summary, aerobic basidiomycetes, such as Ganoderma species, Pleurotus species and Trametes species are most frequently used in the cultivation of mycelium or mushroom.

Basidiomycetes exhibit superior characteristics for producing mycelium-based composites (MBC), as they demonstrate consistent and rapid growth rates, and have the ability to utilize diverse organic waste materials as substrates.

Choosing the right species is tough job to make biomaterials efficiently.

When picking species for biomaterial production, researchers consider factors like how dense the mycelium is, how quickly it grows, the cost of the growth media (the stuff it grows on), how harmful it is, how easy it is to grow and the structure of the mycelium.

How to Make Mycelium Packaging Material?

Mycelium packaging material, also known as compostable packaging material, is a sustainable alternative to traditional packaging materials like expanded polystyrene (EPS) or other non-biodegradable material.

The production process of mycelium packaging material involves several key steps.

1. Substrate Selection

The process begins with the selection of a substrate, which serves as the growth medium for mycelium.

Common substrates include agricultural waste, such as wood chips, sawdust, corn stover, straw, husks, bagasse or other plant-based materials.

The choice of substrate can impact the final properties and strength of the mycelium-based composite (MBC). For instance, MBC from sawdust exhibits higher strength as compare to MBC from straw.

2. Sterilization

To create a clean and controlled environment for mycelium growth, substrate should be sterilized at 121°C for an hour.

This step eliminates unwanted microorganisms and ensures that the mycelium can colonize the substrate without any interference.

3. Inoculation

After sterilization, the substrate is mixed with mycelium. After mixing or inoculation, mycelium then begins to grow in network of threads throughout the substrate.

Additional supplements can be added, such as carbon, nitrogen and water for fast and optimum growth.

4. Incubation

The inoculated substrate is placed in a controlled environment with specific temperature and humidity level, especially in dark room.

Temperature: 25 – 30 °C

Humidity: 60-65 %RH

(Change in temperature and humidity level may impact the growth rate of fungi)

During incubation, the mycelium rapidly colonizes the substrate and form a dense matrix.

This growth cycle typically takes 5-7 days depending on the specific type of mycelium strain, substrate and environmental conditions.

5. Molding and Shaping

Once the mycelium has sufficiently colonized the substrate, it is ready for molding.

The mycelium-mixed substrate is placed into molds of desired shapes and sizes.

The mycelium matrix can be molded into specific shapes and sizes during the growth cycle.

This flexibility in shaping enhances the efficiency of manufacturing, as it eliminates the need for additional cutting or shaping.

6. Mycelium Growth in Molds

The mycelium continues to grow and adapt the shape of the molds during growth cycle. As mycelium grows, it forms a network of thread-like structures called hyphae.

These hyphae extend and intertwine for creating a dense, sturdy and interconnected matrix. The growth continues until the mycelium has fully taken the shape of the mold.

7. Drying and Heating

After molding, the mycelium-based material is carefully is dried in an oven at 100°C for 30-45 minutes to stop further growth of mycelium or to solidify the matrix followed by sterilization.

Developments are ongoing for drying and heating in different ways, such as rubbing with herbal oil and cold/hot pressing.

8. Post-Processing (Optional)

Depending on the intended use and application, additional post-processing steps may be employed, such as water resistant coating.

Keep in mind that strength of mycelium based composite (MBC) is highly dependent on fungal strain, substrate type, growth condition, incubation time, additional supplement, fabrication method or post processing.

By utilizing organic waste as a substrate and harnessing the natural binding properties of mycelium, mushroom packaging not only upcycling materials, but also provides a sustainable and biodegradable alternative to conventional plastic packaging materials.

Regulatory Standards and Certifications for Mycelium Packaging Material

For mycelium packaging material, regulatory standards and certifications ensure that the material meets specific environmental, safety, and performance criteria.

Here’s an overview of the key standards and certifications relevant to mycelium-based packaging:

1. Compostability Standards

Mycelium packaging is often promoted as compostable. Meeting these standards confirms that the material can decompose in industrial or home compost environments without releasing harmful substances.

EN 13432 (European Standard for Compostability)

This is the European standard for packaging recoverable through composting and biodegradation. It evaluates biodegradation, disintegration, and the quality of the compost produced.

Requirements: At least 90% of the material must break down into carbon dioxide, water, and biomass within 6 months under industrial composting conditions.

ASTM D6400 (Standard Specification for Compostable Plastics)

The American equivalent to EN 13432, this standard ensures that plastics, including mycelium-based products, will degrade under industrial composting conditions.

ISO 17088 (Compostability Standard)

An international standard that defines criteria for the compostability of plastics. It requires testing in composting environments to verify that the material biodegrades without leaving toxic residues.

2. Biodegradability Standards

These standards assess whether mycelium packaging materials break down into natural substances over time, particularly in soil or marine environments.

ASTM D5988 (Standard Test Method for Determining Aerobic Biodegradation in Soil)

This test evaluates how well the material biodegrades in soil, ensuring that it will decompose without harming the environment when disposed of naturally.

OECD 301 (Biodegradability Test)

This is a set of tests by the Organisation for Economic Co-operation and Development (OECD) to determine if a material is readily biodegradable in aerobic conditions.

3. Food Safety Certifications

If mycelium packaging is used for food contact materials, it needs to comply with food safety regulations:

FDA 21 CFR (U.S. Food and Drug Administration) for Food Contact Materials

Ensures that materials like mycelium packaging are safe for direct contact with food. It requires that the material does not release harmful chemicals when in contact with food.

EU Regulation No. 10/2011 (European Food Safety Regulations for Food Contact Materials)

In Europe, this regulation outlines the requirements for food packaging materials, including testing for migration of substances from packaging into food.

4. Toxicity and Heavy Metal Content

These standards ensure that mycelium packaging does not release harmful chemicals or heavy metals during degradation.

OECD 208 (Terrestrial Plant Toxicity Test)

This test assesses whether the degradation products of mycelium packaging materials affect plant growth.

EN 13432 and ASTM D6400 (Heavy Metal Content Tests)

Both compostability standards require testing for heavy metals like lead, cadmium, and mercury to ensure they are within permissible limits, making the compost safe for agricultural use.

5. Sustainability Certifications

Some third-party organizations certify packaging materials based on their environmental impact, renewability, and sustainability.

Cradle to Cradle Certified™

This is a certification that evaluates a product’s sustainability over its whole life cycle, from production to disposal. The material health, potential for the circular economy, and usage of renewable energy may all be assessed in mycelium packaging.

BPI (Biodegradable Products Institute) Certification

This North American certification program verifies that products, including mycelium-based packaging, are compostable in industrial composting facilities.

6. Forest Stewardship Council (FSC) Certification

If any wood or agricultural by-products are used in conjunction with mycelium in the packaging process, obtaining FSC certification ensures that the materials are sourced from responsibly managed forests.

7. Ecolabels

OK Compost (TÜV Austria)

TÜV Austria’s “OK Compost” label certifies that the material is suitable for industrial composting. For products compostable at home, the “OK Compost HOME” label is applicable.

EU Ecolabel

This label certifies that a product meets high environmental standards throughout its life cycle, from raw material sourcing to disposal.

By ensuring compliance with these standards and certifications, mycelium packaging materials can guarantee safety, environmental responsibility, and commercial viability in different markets.

Properties of Mycelium Packaging Material

Mycelium packaging material possesses a set of unique properties that distinguish it as a sustainable and green alternative to traditional plastic packaging material.

These key properties contributing its growing popularity in various industries. Here are the standout characteristics of mycelium packaging material as a best green alternative.

1. Biodegradability

One of the most significant features of mycelium packaging material is its biodegradability.

Unlike non-biodegradable materials such as plastic or styrofoam, which persist in the environment for 500-1000 years, mycelium-based materials naturally break down into organic compound in 45 days.

When disposed of, mycelium packaging material breaks down naturally over time and enrich the soil health and fertility by leaving minimal environmental footprint.

Certain companies incorporate plant seeds into their mycelium packaging material to enhance its positive environmental impact by promoting biodiversity.

2. Customizability

Mycelium can be molded into a variety of shapes and sizes, which are making them highly customizable for different packaging applications.

It can be used from protective packaging of fragile items to intricate designs and even in construction material like eco-bricks.

3. Lightweight and Sturdy

Mycelium-based materials are lightweight yet sturdy, making them suitable for protecting fragile items during transportation.

Despite its lightweight nature, mycelium packaging material exhibits impressive strength, durability and structural integrity.

| Mycelium-based Bio-Composites (MBB) | |

| Density | Compressive Strength |

| 280 kg/m³ | 570 kPa |

4. Insulation

The mycelium packaging material provides excellent insulation properties, making them suitable for products that require thermal protection.

For example, It can be used in industries where temperature control is crucial, such as in the packaging of food or pharmaceuticals.

5. Versatility

Mycelium can grow on various organic substrates, including all agricultural waste.

This adaptability makes mycelium packaging material a flexible solution that can utilize different feedstocks and reducing waste that would otherwise be burnt or discarded.

6. Rapid Growth Cycle

Mycelium has a relatively fast growth cycle. Under controlled conditions, it can spread and colonize a substrate in 5-7 days.

This efficiency makes mycelium an attractive option for the production of packaging materials, especially when compared to the longer production cycles of some traditional materials.

Practical Applications and Implementation of Mycelium Packaging Material

Several companies have recognized the potential of mycelium packaging material and have already integrated it into their operations.

Packaging for electronics, furniture, food products and even fashionable items are the examples of successful implementations.

Ecovative Mycelium Packaging

Ecovative Design is a pioneering company in the development of mycelium-based materials and has a patented process for mycelium manufacturing and processing.

They have gained recognition for creating sustainable alternatives to traditional plastic packaging, including protective packaging and insulation.

They have collaborated with various companies, such as IKEA and Dell to integrate mycelium packaging material into their supply chains.

Ecovative has developed many sustainable products, such as MycoComposite, MycoFoam, MycoFlex and MyForest Food.

These innovative products highlight Ecovative’s commitment to sustainability and their creative use of natural materials to address environmental challenges.

MycoComposite

The MycoComposite has achieved biggest commercial success, which is evidenced by its partnerships with furniture giant Ikea and computer company Dell.

MycoComposite uses mycelium, along with agricultural waste like corn stover or woodchips or straw to form lightweight and sturdy material for protective packaging.

It is developed as an alternative to expanded polystyrene (EPS), commonly referred as styrofoam.

Leather – Forager Hides

Leather sourced from animal requires extensive amounts of energy resources, involve numerous processing steps and require distant transportation before reaching to the end user.

While fungi can grow anywhere with less water and land.

According to certain estimates, in comparison to animal-based leather, mushroom-based material utilizes 70% less water, requires 17% less energy and emits 68% lower greenhouse gas emissions.

MycoFoam – Forager Foams

MycoFoam is breathable, insulating, water-repellant and naturally fire-resistant.

Forager™ foams represent an open-cell material composed entirely of pure mycelium, offering full compostability.

MycoFlex – Forager Foams

MycoFlex represents a 100% mycelium-based product crafted into high-performance flexible foams, serving as an eco-friendly substitute for polyurethane and various expanded plastic foams.

These material can be used for various purposes, such as hand bag, footwear and many more.

MyForest Foods

Ecovative is also harnessing mycelium to produce meat alternatives.

MyForest Foods cultivates and harvests nutritious mycelium for ready to eat in just a week by using Ecovative’s AirMycelium technology.

Comparatively, it is taking just a week, in contrast to six months for a pig and approximately three years for a single cow.

Replacing animal products with plant-based alternatives has the potential to significantly decrease carbon footprint and enhance human health.

IKEA Mushroom Packaging

IKEA, the Swedish company for furniture and home goods retailer, has shown interest in mycelium-based materials for their packaging and other applications.

In 2016, with a goal to minimize plastic’s impact on environment, the company collaborated with Ecovative to eliminate all plastic packaging by 2028.

Dell

Dell, the multinational technology company, has been exploring sustainable packaging solutions in their packing operation.

Dell has collaborated with Ecovative to develop a mycelium foam cushion for packaging their laptops.

This initiative aims to reduce the environmental impact of packaging materials.

Top 5 Mycelium Based Products

Fungal packaging material, also known as mycelium packaging material, is an innovative and eco-friendly alternative to traditional packaging materials like plastic or styrofoam. Here are five practical examples of fungal packaging.

1. Laptops and Electronic Devices

Mycelium packaging material can be customized to provide protective casing for electronic devices like laptops.

Its shock-absorbing properties make it an ideal material to protect delicate electronics during shipping.

The mycelium structure molds around the shape of the device, offering a snug and secure fit that minimizes the risk of damage.

2. Fresh Food Product and Perishable Goods

Mycelium-based packaging can replace traditional styrofoam or plastic trays for packaging of fruits, vegetables and meats.

This is not only reducing plastic waste, but also helps to extend the shelf life of perishable foods due to inherent microbial property of mycelium.

Its natural insulation properties helps to maintain optimal temperature and humidity levels, extending the shelf life of perishable goods.

3. Biodegradable Plant Pots and Seed Starters

Fungal packaging material can be used to create biodegradable plant pots and seed starters.

These pots can be directly planted into the ground, eliminating the need for plastic pots or bags that often end up in landfills.

As the mycelium breaks down, it enriches the soil with nutrients, promoting healthy plant growth.

4. Eco-Friendly Furniture

Fungal packaging material can be utilized to create eco-friendly furniture components such as tabletops, chair backs or decorative elements.

By molding mycelium into desired shapes and sizes, manufacturers can produce lightweight yet sturdy furniture pieces.

These items offer a sustainable alternative to traditional wood or plastic furniture, reducing reliance on non-renewable resources.

5. Biodegradable Packaging for cosmetics and Personal Care Products

Fungal packaging material can be used to create biodegradable containers and packaging inserts for cosmetics, skincare products and personal care items.

These products often come in plastic containers that contribute to environmental pollution.

By utilizing mycelium-based packaging, companies can offer sustainable alternatives that are both functional and environmentally friendly.

Challenges of Mycelium Packaging Material

While mycelium packaging material presents various environmental and sustainable advantages, there are also potential challenges associated with its adoption and widespread use.

1. Environmental Impact

Being a fungus, it absorbs oxygen and emits carbon dioxide during its growth, which is the reverse process of plants.

Widespread cultivation of mycelium on a large scale could result in elevated levels of carbon dioxide in the atmosphere.

2. Consistency and Standardization

Achieving consistent material properties and quality across batches can be challenging.

Variability in environmental conditions, strains of mycelium and substrate sources may lead to differences in the final product.

3. Scaling of Production

Scaling up mycelium production to meet industrial demands may pose challenges.

The current scale of production may not be sufficient to replace large-scale traditional plastic packaging materials.

4. Cost Competition

Mycelium packaging material faces competition with well-established and cost-effective traditional plastic packaging material.

Convincing industries to switch to mycelium may be challenging without clear economic benefits.

5. Durability and Performance

When compared to plastics like polystyrene in terms of durability, it is less preferred for applications such as food container.

As per the World Economic Forum, a drawback of fungi packaging is its shorter lifespan in comparison to plastic.

Since the material decomposes within just a few weeks, it is not suitable for companies engaged in shipping over long distances.

Technological Improvement in Mushroom Packaging Material

Scientists are exploring ways to enhance the material’s properties, improve the production process and make it more cost-effective.

Additionally, collaborations between industries and environmental organizations are helping to promote mycelium packaging as a green alternative to plastic packaging.

Here are some general areas of ongoing research and development in mushroom packaging material.

1. Production Process Optimization

Researchers are working on refining and optimizing the production processes of mycelium-based materials to achieve greater scalability, consistency and cost-effectiveness.

This includes experimenting with different substrate formulations, growth conditions and post-processing techniques.

2. Standardization and Quality Control

Efforts are underway to establish standardized protocols and quality control measures for mycelium production.

Standardization is crucial for ensuring consistent material properties across different batches and meeting industry standards.

3. Material Performance Enhancement

Researchers are focused on improving the mechanical, thermal and protective properties of mycelium-based materials.

This involves exploring different strains of fungi, twist growth conditions and experimenting with additives to enhance the material’s overall performance.

Continued research into the genetic engineering of fungi to enhance mycelium properties, such as strength, flexibility and resilience.

4. Diversification of Feedstocks

Ongoing research aims to diversify the types of organic waste used as feedstocks for mycelium production.

This includes investigating the feasibility of using agricultural residues, forestry byproducts and other waste streams to make the process more versatile and sustainable.

5. Bio-Bricks

Through precise selection of fungi strain, environmental conditions and substrate composition, researchers have optimized the strength, durability and insulation properties of the bio-bricks.

Some types of fungi can make a material called calcium carbonate. This material can fix cracks in buildings and be used in bio-concrete.

By genetically transforming these calcite-producing strains into composite-forming fungi, the quality of the composite material can be significantly improved.

6. Life Cycle Assessment (LCA)

Ongoing research involves conducting comprehensive life cycle assessments of mycelium packaging material to evaluate its environmental impact throughout its entire life cycle.

This includes assessing factors such as carbon footprint, energy consumption and end-of-life considerations.

Conclusion

By choosing mycelium packaging material over plastic, businesses and consumers contribute to the reduction of plastic pollution.

Plastic pollution, particularly in oceans and landfills poses significant environmental threats.

Mycelium’s biodegradability helps address this issue, offering a sustainable solution to mitigate the environmental impact of plastic pollution.

FAQs

Yes, currently mycelium packaging is more expensive than traditional plastic packaging. This is mainly due to smaller-scale production, longer growth times, and the need for controlled environments. However, as technology advances and demand increases, costs are expected to decrease over time. In return, it offers long-term environmental benefits that plastic can’t match.

Yes, mycelium packaging is considered zero waste. It’s made from agricultural by-products and fungal mycelium—both renewable and biodegradable. After use, it can be composted without leaving behind microplastics or toxic residues. Some versions even contain plant seeds, turning waste into new life.

Mycelium packaging biodegrades in 30 to 45 days under composting conditions. In natural soil, it may take slightly longer, but it still breaks down far quicker than plastic, which can take centuries. The decomposed material improves soil quality and leaves no harmful trace.

The longevity of fungal mycelium varies depending on factors like species, environment and substrate, but it can persist for weeks to years.

Yes, mycelium can be used for food packaging as it is natural, biodegradable, and compostable. However, it may need a protective coating to ensure food safety and moisture resistance.

Humidity levels directly affect mycelium growth by providing the necessary moisture. High humidity encourages growth, while low humidity can hinder it. Maintaining optimal humidity is crucial for successful mycelium-based product creation.

The optimal growing conditions for fungal mycelium typically include factors such as suitable temperature, moisture levels, pH balance, and nutrient availability.

Temperature: 25 – 30 °C and Humidity: 60-65 %RH

Mycelium development is evaluated by examining chemical and physical factors, including visual inspection, pH levels, organic matter content, water content and the morphology of the mycelium surface.

Extended growth periods lead to increased organic substrate degradation, resulting in fewer substrates and more hyphal structures. As the compressive strength of MBC mainly relies on substrates, longer growth times consequently lead to reduced compressive strength.

Nutritional content, availability, degradability, cost, structural properties and compatibility are the factors shall be considered.

Attn. Director,

We are interested in your products. Please contact us with product details/catalog and price list if your company can handle a bulk supply of your products to Cameroon.

Please send your reply to [email protected]

HRM Bah Mbi